UNDER THE SKIN: THE UNDERDOG – DAMIAN MILANO IMPROVED PRODUCTION CLUBSPORT

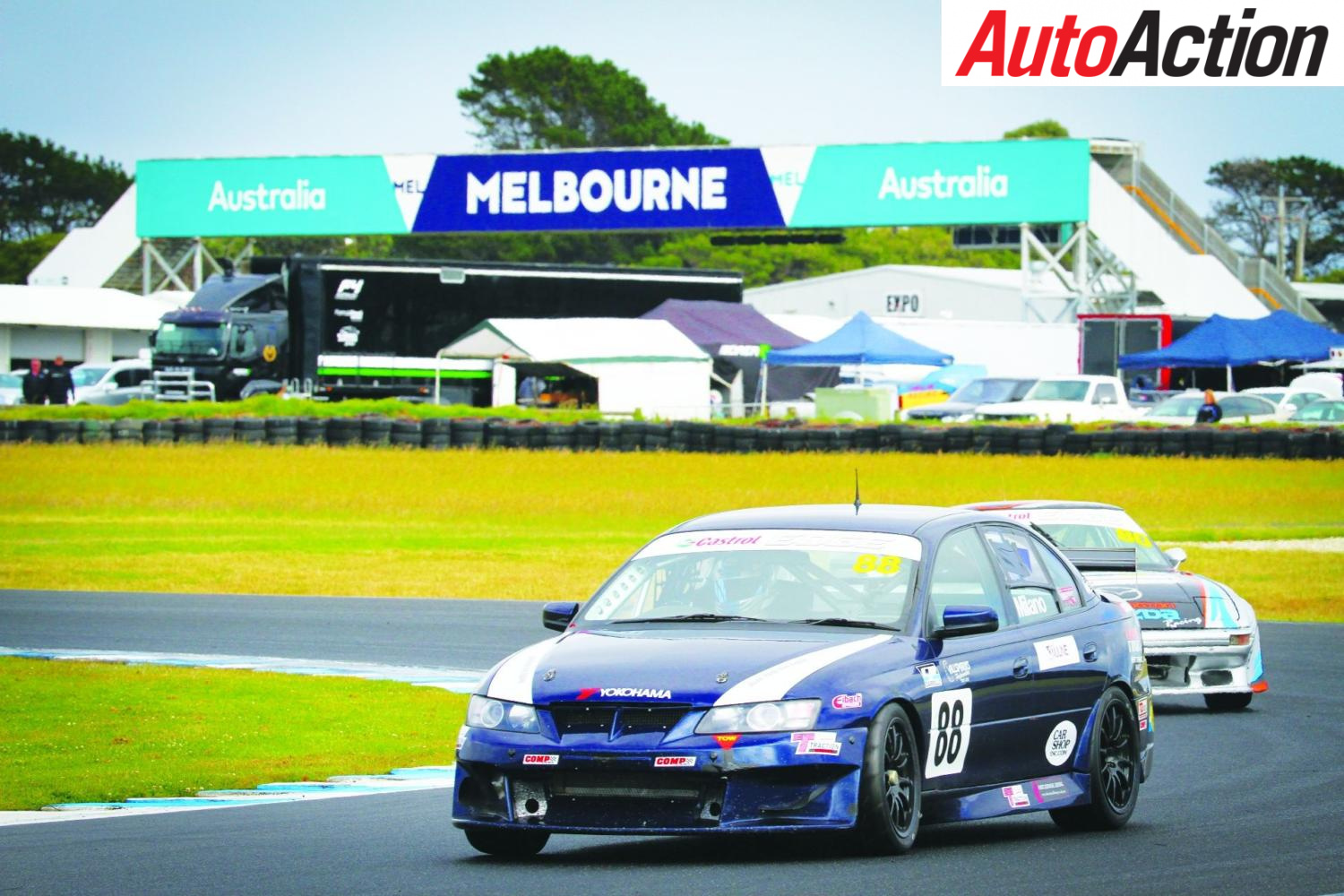

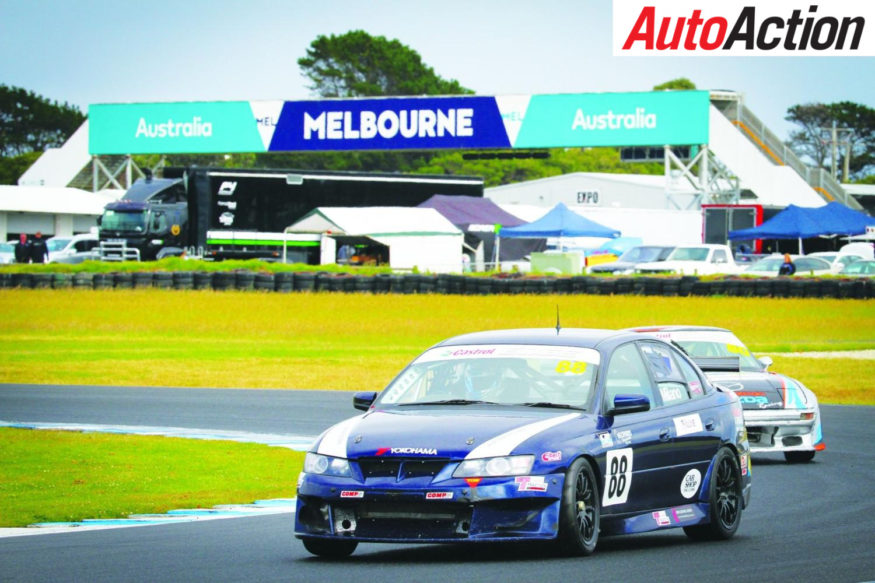

Damian Milano’s Improved Production HSV VY Clubsport

Damian Milano has gradually modified his HSV VY Clubsport to the point where it has won State Championships and is a National frontrunner, but it has come a long way from its humble beginnings as Milano’s road-going car

By HEATH McALPINE

IMPROVED PRODUCTION has one of, if not, the most diverse field seen on Australian race tracks.

Not only are the cars different, but so is the way that each individual car gets onto the race track. This diversity cannot be more highlighted by comparing two key rivals in the Improved Production category, Ray Hislop and Damian Milano.

As covered in Auto Action #1699, Hislop’s car is a well-developed, purpose built race car originally built using a bare shell from Ford. On the other hand Milano used his HSV VY Clubsport as his road car before entering sprints and deciding to take motor racing just that tad more serious. The word ‘tad’ might be a bit of an understatement, as he has fully transformed his HSV into what is currently one of the quickest Improved Production cars in the country, while also having to deal with the restrictions of using a road car shell while trying to get the best out of a car that doesn’t entirely suit the Improved Production rules.

“I first started back in 2008 doing sprints with the HSV Owners Club of Victoria for two or three years,” Milano explains. “I was looking to progress and do something a bit different and at that point it was a road going converted car so we caged it and went down the path of making it a log booked 2J car to run in Improved Production and that’s where it all started.”

Milano’s Clubsport is quite a successful car, having placed third in the 2016 Improved Production Nationals at Hidden Valley. It has taken Milano to three Victorian Improved Production Car titles and was well in contention to grab second at last year’s

Improved Production Nationals at Phillip Island until a spin dropped him out of the running.

Development of the Clubsport for last November’s Nationals had started 12-18 months prior, with Milano’s small team trying to find the maximum improvement through the handling of the car.

“About 18 months ago we set ourselves for last year’s Nationals, we ran at the 2016 Nationals in Darwin and finished third, but straight after that we said we needed to make improvements,” says Milano.

“The rear wasn’t overly settled in the car, so we have gone to a Penske rear shock, but when we put that in we started having some issues in getting the set-up of the car right. We’ve had a few goes at it, we changed the alignment on the rear and we’ve made huge improvements. It’s still not perfect but there are massive improvements from where it was 12 months ago or even early last year. The car has been very loose through the high speed sections so we’ve been looking to improve that.”

And for a track like Phillip Island, where the corners flow together and the top cars clock a 1:40 lap time it was essential for Milano to try and combat the problem. Milano’s team have found the right set-up with the Penske shocks on the rear, but at the front of the car, Koni shocks have been installed, due to fitting in the VY a lot easier than the Penskes.

“We’ve just manufactured Koni front legs because to get Penskes to go in the front on the strut suspension we have on the VY Commodore is not very easy. It would have been a whole lot more expensive to run the Penskes, not impossible, but we’d have to make a front leg, whereas the Konis were a lot easier to make a front leg. We put Konis on the front and Penskes on the rear.”

Damian Milano runs lighter Team Dynamics 18×9” rims

Milano runs lighter Team Dynamics 18×9” rims, the maximum size he can run in Improved Production, while Yokohama O50 tyres are the control tyre for Improved Production.

Much like most of the more modern machinery in the field Milano has a couple of aerodynamic features that are different to the bodykit seen on a stock VY. Milano’s car runs a rear wing, which has been specifically produced for the category and a modified front bumper.

Damian Milano’s car runs a specifically produced rear wing for Improved Production

“I had someone make the front bar and rear wing,” explains Milano.

“They were made over in WA, it’s the Improved Production spec. It can only be 200mm off the boot lid and no more than 200mm long and it’s everything as you see on all the late model cars. The body kits, wings and front spoilers have to be flat on the bottom; they can’t protrude forward any further than the factory front splitter. There is a small amount of aero on the car but it’s not a huge amount, it’s mainly being able to get grip in the tyres to be able to maintain good corner speed.”

The development of the car has seen Milano try and improve the car by replacing the engine, gearbox and trying to remove the weight out of the car, but unlike most cars on the grid it has been a staggered process for Milano and his team.

“Most competitors bring something that they’ve had or something that they like or that they want to race then there are others that go and get a write off and build a purpose-built race car from the ground up. I haven’t done that,” Milano says.

“This has been converted and it’s probably why it’s not perfect because it was done over a long period of time, it wasn’t completely stripped out at all in one go, we’ve done it progressively. When you do that you probably leave a few things here and there you probably wouldn’t normally do if you build a purpose built race car from straight off the production line. It’s just an evolution more than anything else that was the reason why it was done that way; we’ve just evolved the car from what it was as a road going car to what you see here now. It looks like it’s pretty competitive with the top couple of National competitors.”

Evolution has seen the car dramatically change from initially a lightly modified road car to a heavily developed and extremely quick race car as Milano explains.

Damian Milano’s race spec 6-litre engine

“When I first started in Improved Production I just had the 7-litre engine that was installed in the standard car, with some modifications. Now, we have gone to a more race spec 6-litre engine, we’re running virtually ex-V8 Supercar brakes, it runs a Holinger six-speed H-Pattern gearbox; it’s a category restriction that it can’t be a sequential gearbox.

“Then taking out all the interior and other things permitted by the Improved Production regulations. Now even the door trims can be replaced with carbon fibre ones, just to try and reduce the total mass of the car. We’ve gone down the road of taking everything out that isn’t required or can be reduce.

“There are still a lot of heavy things in the car that can be improved; it just takes a lot of time to work through that.”

The engine has seen plenty of development, but reliability was lacking, as Milano laments.

“A part of the category rules, which is a bit of an issue for us, is that we have to run a factory block. We have had a lot of engine issues over the journey with these aluminium alloy blocks. The LS generation are not really suited to the rigours and needs we want out of a race engine. It’s not really ideal. They are a cast and sleeve into the block and the whole design is never ideal. It wouldn’t be what you’d use if you were building an engine from scratch for a race car but we have to run it under the rules for this competition.”

Milano has taken advantage of the limited freedoms the Improved Production regulations allow and has seen improvements in reliability once he started using E85 fuel.

“We’re running the factory block, aftermarket heads, an LS7 factory manifold, not an LS2 or 3, a 90mm Holley throttle body, a Kelly’s crank, rod and piston combination, so it’s fairly lightweight and we get a bit more RPM out of the engine,” Milano explains.

“We run a Motec engine management system and apart from that it’s fairly production based, unfortunately.

“That’s one of the limitations that we’ve been finding, it’s been a big issue for us to try and get our engine suitable to run in races lap after lap after lap because it’s not like drag racing or other forms of motorsport that is short and intermittent. The engines have to be really tough to last a 10 or 11 lap final, on top of the heats.

“To try and give ourselves a bit more security in our engine tuning, we have now switched to E85 to give us a bit of security with the higher octane of the fuel. Then there is a bit of a trade-off because we have to carry a lot more to make the race distance.”

Milano claims to have over 600hp in his Clubsport, more than a Supercar. But due to the engine using a standard block, among other things, the engine is much more restricted in its design and less effective than a Supercar engine.

“Higher 600hp range,” says Milano. “Probably putting out more than a V8 Supercar would, which is 5ltr, we’re running 6ltr. Not a lot more, but it’s just limited by what we can and can’t do with the engine.

“Its design and there are a lot of things that come out of that, we’re only running a factory plastic manifold, we haven’t gone to an eight throttle body manifold just because we don’t see an advantage, it’s going to be marginally heavier and a lot more expensive.”

Milano is finding more value in developing the braking and handling of the Clubsport and sees those as the key areas where the car will improve in the future.

“We’re just trying to get bang for buck with whatever we do. I found that doing work with brakes and suspension is better than chasing a heap of outright horsepower; I’m not saying we have a heap of outright horsepower but it’s probably not the one thing that we’re chasing in the outright package.”

Damian Milano’s Improved Production HSV VY Clubsport

Milano is still developing the car and is more than competitive amongst the likes of Matt Cherry, Justin Keyes, Ben Schoots, Grant Maitland, Nathan Geier and Leigh Forrest, but acknowledges Hislop is still very much the man to beat.

“It’s been very competitive at state level and also competitive at national level,” enthuses Milano. “There are people like Ray Hislop who drive a very special car and he’s a very good driver, but there’s always someone out there trying to do better and we appreciate that, we want to be as good as we can be too.”

“There’s a bar that’s set, it may be very high, but everyone is doing the best they can to get as close as they can to him [Hislop].

Like we did in race one at the Nationals, though it wasn’t under usual circumstances, but you take that any day of the week.”

Milano’s car is proof of how accessible Improved Production is, but also how much experimentation and time it takes to make a car competitive in the class. Many of the cars up the front are close to 20 or 30 years old and are still being developed, hence why the class has seen extreme growth. Milano will be looking forward to making further in roads on Hislop and his BF Falcon.

“It’s come a long way from a road-going car and so has its pace. When you get to that front-running level of the category there are some pretty fast cars. Hislop broke the lap record at last year’s Nationals, at a sub-1:40s. It’s a very fast category.”

After Auto Action’s latest Under the Skin feature? Pick up the latest copy of magazine, in stores Thursday. Also follow us on social media Facebook, Twitter and Instagram for all the latest news.