UNDER THE SKIN: RAY HISLOP’S IMPROVED PRODUCTION FALCON

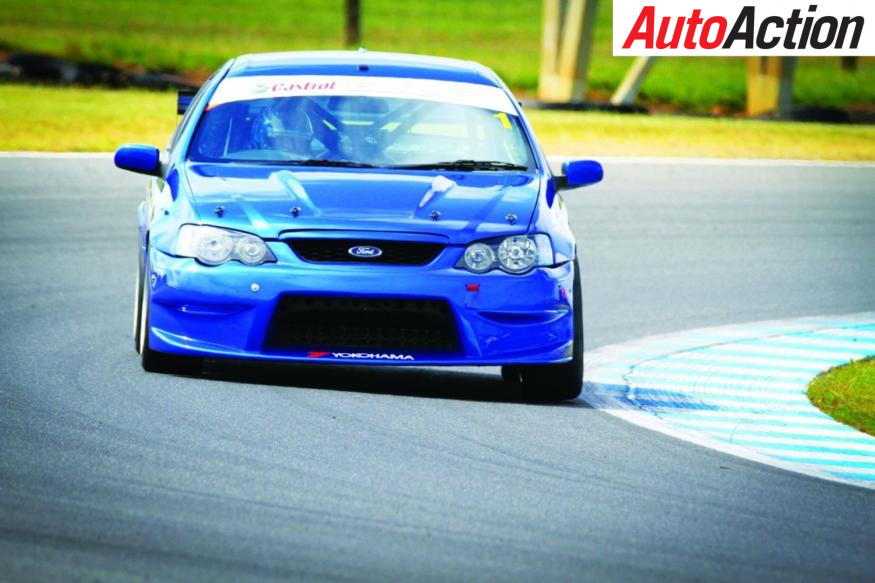

Ray Hislop’s Ford BF Falcon Improved Production Car

IMPROVED PRODUCTION is a rather surprising category where innovation and engineering through constant test and development provides some of the best racing in Australia.

A typical grid can include anything from Mazda 808s from the 1970s to the latest VF Commodores, but one car has proven to be the one to beat for the best part of nearly 10 years – Ray Hislop’s Ford BF Falcon.

Hislop’s racer is a true representation of how highly developed an Improved Production car can be. The car has experienced nothing but success since its debut in late 2008, and has won the annual Improved Production Nationals for four out of the last five years, most recently the 2016 title at Phillip Island.

Improved Production is experiencing a rise of well-prepared and highly-engineered cars taking the field, raising the bar in car preparation, innovations in suspension, dampers and brakes, engine development and weight reduction.

Ray Hislop’s Ford BF Falcon Improved Production Car

The Falcon started off as a factory shell from Ford with just the hang-on panels and took three years to build, but most recently car and driver have really hit their stride, as Hislop explains.

“The last three years, maybe four years we’ve really got on top of what this car wants, the benefits also of that time period is the Yokohama AO50 control tyre that our category runs came on board and it transformed this car,” said Hislop.

“It was pretty much an understeering pig for a lot of years but once we got that tyre, it was a tyre that we could work with. We’ve gradually been stiffening the car, to the point where our front and rear spring rates are nearly double what they were on the previous tyre. We’ve just been making it stiffer and stiffer, and the car’s getting faster and faster.”

A lot of the gains Hislop has made are not through engine development but rather through suspension and weight distribution. With the help of suspension guru Rick Kemp, the car has been transformed into one that has excellent tyre life while still achieving high grip levels.

Suspension work on the Ford BF Falcon

“We’ve used Rick a lot and he’s completely transformed his car,” says Hislop.

“Rick has been instrumental in getting this car consistently up the front, to a point where we have it in a window where no matter where we take it, it’s fast.

“Most people believe that to go fast, you need horsepower. On some circuits it’s vitally important that you have power, but our engine hasn’t had any upgrades done to it for a minimum three years, possibly longer. But what we have worked extremely hard on, with Rick, is the suspension and the braking package, and that’s where we are seeing the gains.”

Alcon brake callipers and rotors from a 2011 V8 Supercar helps the car stop. Also, Hislop was running different brake compounds at Phillip Island, which gave him more confidence in key braking areas, such as turn four.

“We’re actually running different brake compounds this weekend for the first race meeting and we’re seeing on our data that we’re consistently 16 to 18 metres deeper braking into Honda (Turn 4) and that’s obviously improving and lowering our lap times,” he said. “The car, it’s settled under brakes; it’s been a big win for us.”

The V8 engine found in the Falcon is built by Dave Harvey at Noonan Race Engineering, which also builds engines for Brad Jones Racing in the Supercars Championship. A stipulation of the Improved Production rules is that the car must retain its road car block, but Hislop has found it to be to his advantage, unlike some of his rivals.

V8 Engine in the Ford BF Falcon

“They’ve tried to replicate a current V8 Supercar-spec engine with the throttle bodies and the intake cylinder head designs, but we have the advantage that we can run to a six-litre capacity, not five litres. It makes good power, good torque, it’s reliable, and we don’t rev it much past 7000rpm; at Bathurst, we’ll take it to 7500rpm down Conrod.”

Helping to put the power to the ground is a Hollinger six-speed H-Pattern gearbox that feeds power to a nine-inch independent rear end. Hislop has safeguarded himself from failure by running stronger CV Joints and bigger driveshafts. These parts have been in the car since the start and ‘touch wood’, have proven to be bulletproof so far.

Weight is a key issue, as it is for any competitor who chooses a Falcon or Commodore, but again Hislop has gone to great lengths to take unnecessary weight out of the car. Recently he has taken the air jack system out of the car, saving a significant amount of weight.

“Weight is the killer for us and our minimum weight for our car in this category is 1455kg with the driver, well I’m still 120kg overweight,” laments Hislop.

“There is no way I can get that out of it. We’ve worked on suspension, brakes, but we’ve traditionally had an air jack system on the car. We don’t do endurance racing, hence we don’t do pit stops, but it’s a convenience thing when we service the car, so again in the last six months we’ve taken them off, because we lose 18.5kg, which is massive. To be able to take it off, we now just have an airbag system that we jack it up when we’re in the pits, so all of a sudden we lose 20kg of weight out of the car.

You can work for years and years cutting bolts down and fabricating new lighter brackets to get that gain.”

Though having a well set-up car was the main aim for Hislop, safety was paramount so Hislop has had a significant roll cage structure installed that has thankfully kept him safe. Incidents at the past two Bathurst 12 Hour Improved Production support races have tested the strength of the roll cage and, thankfully, it has passed the test.

“The roll cage is a chrome moly cage, which has the lightweight chrome moly and it has had an engineering certificate. Again, it’s got more cage in it that we probably needed but I decided to do that because the most important thing was safety with the car. I unfortunately have had accidents at Bathurst the last two years, so I have dented the car a few times, but at no point have I been in any danger, which is paramount to me and to my wife.”

Aerodynamics are really not in play in Improved Production, though front and rear bumpers can be of free design but must retain the silhouette of the original and cannot extend past the foremost part of the original bumper. Hislop isn’t sure how much it aids the performance of the Falcon but maintains mechanical grip is most important.

Improved Production is more about mechanical grip than aero

“The cars aren’t designed to be aero driven; they’re designed just to have mechanical grip, which is all we get not aero grip,” he explains.

“The rear wings we’re allowed to have are a wing that fits within a 200x200mm box section from the height of the boot, and to what effect it has, I can’t tell you because I haven’t taken it off ran the car without it. That would be the only way to confirm it, we don’t measure how much load we get through it.”

Hislop has done a lot of work with control tyre supplier Yokohama to combat the weight and sidewall failures seen in the heavier V8 cars. The result has seen the sidewall failures fixed and Hislop’s car now enjoys strong tyre life and plenty of grip.

“We’ve done a lot of work with Yokohama in the last 18 months as well, because we’ve had some tyre issues that some of the later model front-engined, V8 cars were having sidewall failures, but Yokohama and I worked to resolve that issue now. We see no tyre failures; the tyre life is excellent on this car; again if you’re not wheel spinning and if you’re not sliding, you’re not wearing tyres out. Even though we’re going faster and we’ve got a lot of grip, we’re not actually wearing components out.”

Hislop has also found a sweet spot with the Falcon thanks to the suspension work and the new tyres from Yokohama, which enables him to be consistently fast. Proof of this was when Hislop was caught out by a red flag in qualifying at the most recent Nationals and had to start near the back of the field, but he and the Falcon recovered to lose out on the race by a car length.

“We’re now not burning tyres as much and all of a sudden the car can now be consistently faster, which allows you to go deeper into races with good speed, allows you to catch guys that start well then within two or three laps, rear tyres start to go away and they’re sliding and spinning. We’ve had that and we’re not doing that now. These tyres are that good we’re still not seeing the full potential yet.

Victoria’s Damien Milano and Western Australia’s Matt Cherry uphold the V8 honour in their HSVs with both improving dramatically over the last couple of Nationals meetings. Hislop welcomes the challenge as he continues to strive to get the most out of the car.

“We’ve got to keep on pushing ourselves and for me it’s guys like Damien [Milano], he’s really in the last two years lifted where he has come from and he gets it,” says Hislop.

“We’ve been doing it and Damien gets it, and there are a few others, but there are a lot of cars in our category that can benefit from having one guy for one day that actually has some clue about the shock absorbers.”

GoPros have become very important in motorsport in regards to filming incidents, but Hislop also pairs it with data to see what he can change in his driving style to suit new set up tweaks. It also helps the suspension guys to decipher what he is doing in the driver’s seat.

“It’s always good to have a look but interestingly, we use the in-car footage with our suspension guy, because he can see the data that comes from the car. But sometimes a visual tool is as good as the data, therefore he can see the lines that I’m taking on the track, gears that I’m in, whether I’m trying to torque the engine out or rev the engine in and out of corners. We change where I’m driving on the track and sometimes what gear I’m using to determine if it is faster, is it slower, is it the same.”

There is no question Hislop has moved the goalposts, but there are many competitors such as Milano and Cherry, that are steadily catching the blue Falcon. This is why he keeps developing and finessing the Falcon and, he says, why the class is so competitive and so popular.

Ray Hislop’s Ford BF Falcon Improved Production Car

“We’ve got cars that have been around for 40 years still running around and they’re still competitive because no one ever stops developing their cars,” he says.

“Every race meeting we go to, I have done something different on the car. Does it work? Hopefully, sometimes it doesn’t but the old saying, if you change nothing, nothing changes.”

This year, there were 80 over two-litre cars competing at the Improved Production Nationals at Phillip Island. Fifty cars lined up for the final, which Hislop won comfortably, but the battle for second proved extraordinary, with the V8 HSVs of Milano and Cherry battling Ben Schoots in his RX7, Grant Maitland in an Nissan S13 Silvia and Justin Keyes in his Mazda 808. This is the reason why competitors are attracted to the category, according to Hislop; they are able to build and race the cars that take their fancy.

“The good thing about this category is that people build the cars they like, it’s not necessarily which cars going to win,” he enthuses.

“It may never get to the front but if the driver enjoys the build process of the car and then going out and running it, hops out and thinks job well done, that’s what it’s all about.”