THE UNCOVERING OF A LEGEND – WILLIAMS FW07

This is the car that started it all. The Williams FW07 not only vaulted Alan Jones into superstardom but set the trend for the team’s title successes for the next decade. Heath McAlpine revisits an important chassis in Formula 1 history.

Uncovering of a Legend – Williams FW07

Owned by aviation engineer Paul Faulkner, his FW07/04 took four out of six Grand Prix victories with Alan Jones at the wheel in 1980 before making the long journey from the UK to Western Australia, to be displayed as a museum piece for the best part of 30 years.

Faulkner bought the FW07 a decade ago, since which it has received a full restoration under the expert eye of Jones’ former Williams number one mechanic Wayne Eckersley.

Driving his FW07 at a variety of events including the Australian Grand Prix and Phillip Island Festival of Motorsport, Faulkner is never shy to show off his very special part of Formula 1 history.

It was Frank Williams’ third attempt at Formula 1, but it proved the breakthrough when he formed Williams Grand Prix Engineering Limited in 1977 alongside Patrick Head in a 70-30 was split.

Luring disillusioned engineer Head back to Formula 1 after an unsuccessful career to that point proved a masterstroke, and began an iconic partnership which lasted more than two decades.

Using a customer March chassis driven by Belgian Patrick Neve, no noteworthy results were achieved.

For 1978, the first Head-designed Williams, the FW06, improved the fledgling team’s results, so too did the addition of Jones, who finished a best of second at Watkins Glen on his way to 11th in the World Drivers’ Championship.

Increased sponsorship support from the Middle East courtesy of Saudi Airlines and the Saudi Bin Laden Group enhanced the team’s chances ahead of the 1979 season. This led to Clay Regazzoni joining Jones in a second entry in a championship, which was now heavily dominated by ground-effects design technology.

Lotus and its Type 78 started this in 1977, but its failure to close the gap to Ferrari that year saw rivals largely unmoved by ground-effects aerodynamics.

The next year Lotus made all its competitors stand up and take notice. In a season of dominance, Lotus took all before it to win the 1978 World Drivers’ Championship with Mario Andretti.

Lotus teammate, Swede Ronnie Peterson, was posthumously awarded second after his death due to medical complications resulting from an accident at the start of the Italian Grand Prix at Monza.

Lotus was further rewarded with the International Cup for F1 Constructors.

However, it was a short-lived time at the top for Lotus, as in 1979 it went in the wrong direction when designing the Type 80.

This opened the door for Williams, which had acquired a strong brains trust including Head, Frank Dernie, Neil Oatley and even a young Ross Brawn among its R&D team.

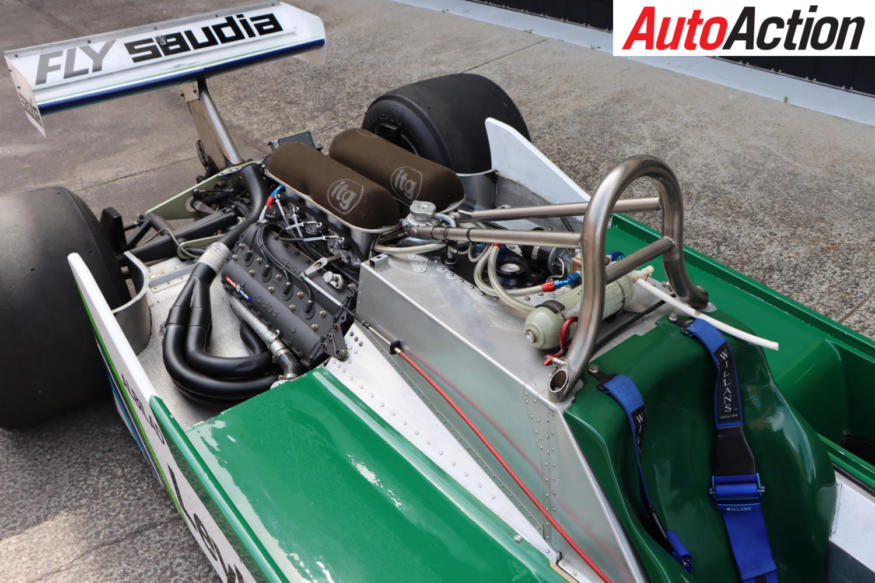

The key difference between the Lotus direction and the one of Williams took proved to be its better understanding of the aerodynamic loads that ground-effects created with the use of skirts, which on the Lotus 80 jammed under high loads.

On the FW07, this was avoided by using aluminium honeycomb and a sophisticated suspension system.

Debuting at Jarama (one was taken to the earlier US West GP, but remained under a tarp), the FW07 retired in its first two races, before Regazzoni scored second in the principality of Monaco.

Then there was a crucial breakthrough.

Dernie hurried back from the Imperial College wind tunnel and worked through the night to construct fairings alongside the engine, which kept the airflow attached.

The impact was felt straight away, as Jones took pole at the British Grand Prix and went onto dominate the race until his engine overheated, handing Regazzoni victory.

Jones went onto win four of the next five races to finish third in the World Drivers’ Championship, sending a message to the Formula 1 fraternity that Williams for the 1980 season.

Three of these Grand Prix victories – Germany, Austria and Canada – were taken in Faulkner’s chassis, so too the season-opening 1980 Argentine Grand Prix.

Jones moved to the FW07B for the rest of the season, when he won his sole-World Drivers’ Championship by 14-points ahead of Nelson Piquet.

For the rest of the 1980 season, chassis FW07/04 was used for testing purposes until trying new tyres Jones crashed at Donington Park.

It was then used by Saudi Airlines as a promotional piece before being bought for the Peter Briggs Collection in York, Western Australia, before the museum moved to Fremantle in 2002.

Paul Faulkner purchased the car on 2010

The chassis then went to auction in 2010, when it was purchased by Faulkner.

“It was about April 2010, it had been in the Peter Briggs collection at the York Motor Museum since 1981, he bought it direct through Williams,” Faulkner told Auto Action.

“It came up for auction, I was umming and ahhing, thinking an ex-F1 car would be something novel and this one was on my doorstep. It got passed in, but I bought it a few days later.”

What followed was the introduction of Jones’s right-hand man during his period of international success, fellow Australian Wayne Eckersley.

“I bought it back and got Wayne Eckersley, who was AJ’s number one mechanic. He came down from Queensland, we had a look at the car, pulled it apart and thought, ‘Geez this is alright’,” recalled Faulkner.

“If it was no good, we were going to put it back together and have it as a display car, but we looked and it was actually a good car. It had a lot of new bits on it, it was complete apart from the engine (which) was hollow, it was just there to hold the back of the car on.

“We said ‘Let’s do it’, so Wayne stayed down here for about eight months with us working part-time. I’ve got some pretty handy people on staff here (Faulkner’s company is Aviation Component Services) to do different machining, welding and painting jobs in-house.

“There was a bit of help from people like Mike Borland, who made new suspension arms for the front because those had been damaged when the car was shipped around the world.”

FW07/04 was stripped down to a bare tub where signs of the skirmish Jones had at Donington Park where still evident and remain today after the refurbishment. “It’s character,” described Faulkner.

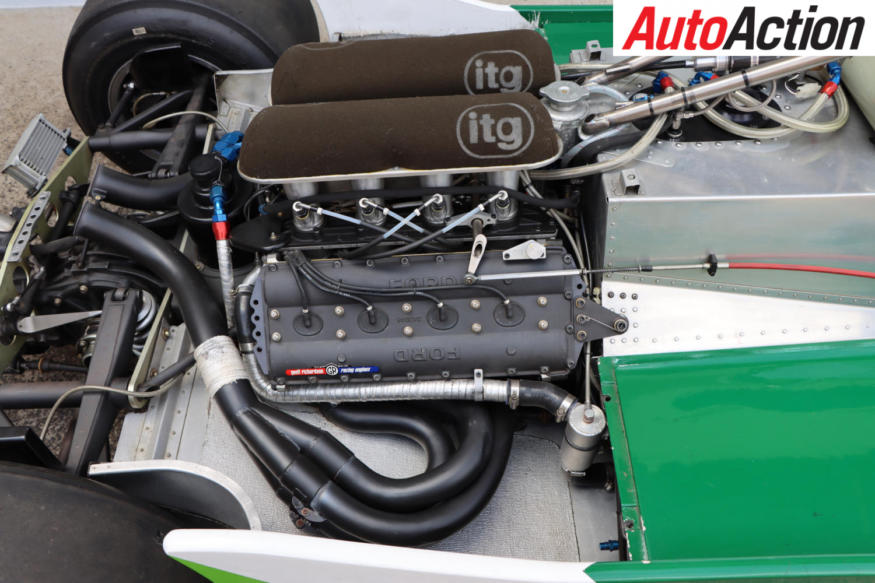

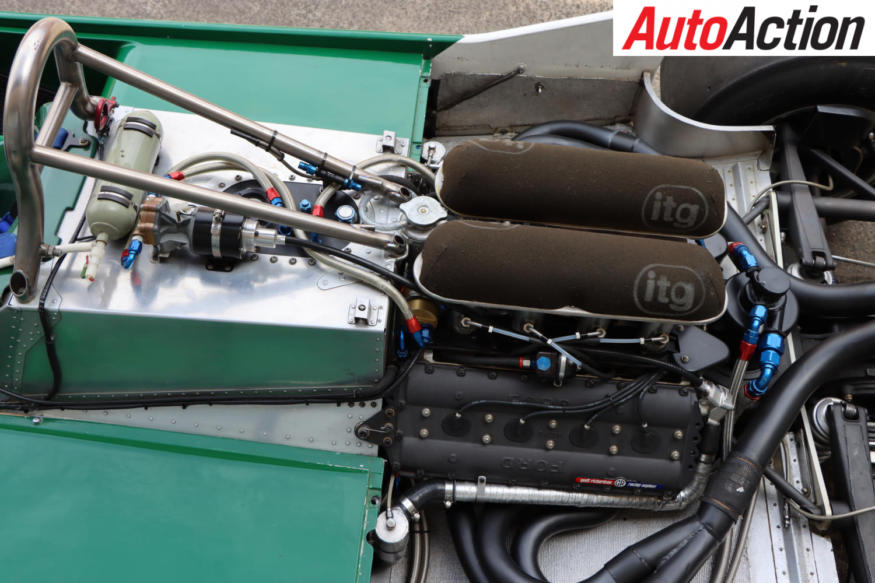

The biggest job was restoring a legendary Cosworth DFV V8 engine, which received a new lease on life when ground effects entered Formula 1 in 1977, a decade on from when it made its Formula 1 debut.

Its competitiveness at the highest level had waned in the mid-1970s after the introduction of flat-12 powerplants from Italian manufacturers Alfa Romeo and Ferrari.

However, the narrower Cosworth DFV allowed venturi tunnels to be created on the underside of the cars, increasing downforce by taking advantage of low-pressure regions found in that area. The V-configuration of the Cosworth engine angled upwards, leaving room for an underbody profile, which also delivered a massive increase in downforce, further enhancing cornering potential and straight-line speed.

From 1978, the Cosworth DFV engine went on to power four out of the next five World Champions before turbos became reliable and more powerful during the mid-1980s.

Faulkner ordered a new engine from a long-time friend of Patrick Head’s, to the exact specification run in 1979, albeit detuned slightly.

“The biggest item was the engine,” Faulkner explained.

“We didn’t have anything useful to work with so we actually bought a complete unit from Geoff Richardson’s in the UK. Geoff has been good friends with Patrick Head since they were lads and they conspired together to give us the right specification.

“Not a super peaky engine, you need more torque due to the drag produced by the aerodynamics. It was a brand new engine that came straight out of the box.”

There was further investigation work that took place for various parts, which was easier due to the FW07/04’s originality.

“There was a lot of investigation work, up all night phoning around England trying to find this or that and learn things,” explained Faulkner. “We were able to get the shock absorbers rebuilt and those were put back in, hydraulics are simple hoses, the car is quite manageable.

“You get later into the 80s with turbos, computers, any car that needs a laptop to make it work is just not my cup of tea.”

Further help was found when a connection of Faulkner’s bumped into a man in England, who owned a considerable spare parts inventory for early Williams models.

“A contact through the racing world happened to be sitting around at Donington or Goodwood racing and at a barbeque ended up telling people that I’d bought a Williams,” Faulkner sets up the story.

“One bloke said ‘I have a lot of parts for them,’ and next thing I know, I’ve got the phone number and it’s like ‘Hey, I hear you’ve got lots of parts for Williams’, ‘Sure do, what do you want?’

“His friend had collected a lot of stuff that was going in the skip at Williams back in the early ’80s and there was an absolute treasure trove. Dymag wheels, I got a couple of sets, the FW07 has got an unusual fuel and oil pressure gauge so he had one of those all very reasonably priced, cheap I would say.

“This guy was just there to help. He had just restored another FW07 and knew his way around them. He was able to lend me a fuel cell so I could send it to the manufacturer because they needed a copy, so he dropped it off on his way to holidays.”

Another link to the Williams puzzle was Rodney Harlow, who led the manufacturing program for Supercars team Ford Performance Racing (now Tickford Racing) and was more than willing to help restore a chassis he worked on during the infancy of his career.

“Rodney Harlow, who was a fabricator for Williams back in the day, actually moved here (to Australia) many years ago and he was running Ford Performance Racing’s manufacturing,” recalled Faulkner.

“He was doing a bit himself and he went out on his own. He said to me, ‘Oh, I helped build that car, if you’re missing anything,’ … ‘I’m missing louvres off the radiator’ was my reply.

“When I went to pick them up, there was a set there, but there were another few sets under the bench. I said ‘What’s wrong with those? They look perfect’ and he replied, ‘They weren’t good enough’.”

Faulkner was delighted to have these two former Williams crew who helped build the chassis originally reunited 30-years later.

In addition to this, many of Faulkner’s crew at Aviation Component Services contributed to the restoration.

“There was a lot of detail work, like the plumbing was all missing, so we had to make it from scratch,” recalled Faulkner.

“That was a real task and one of our guys, Andy, did most of the work very meticulously. He spent days trying to get it right and not just working, but looking right. We didn’t have a lot to work off and you’ve got hoses running around corners, it was a lot of work.”

All other components were stripped down, crack tested and dimensioned before being reinstalled in Faulkner’s workshop.

“We’re proud of what we did with it. It was a lot of work, a lot of people doing stuff, but I think we’ve done a reasonable job of not changing it, respecting it,” said Faulkner.

Faulkner’s connections in the aviation industry also aided in reproducing the wiring in the Williams, though the electronics of the era are very basic and laid out on a one-page diagram.

A lot of the components are basic aviation parts, making it more straight forward item to restore.

“There’s a little battery for the ignition system, it’s got an air motor to start it and there’s an electrical fuel pump, which is only needed to start it,” explained Faulkner. “After that, there’s a rain light and that’s about it.”

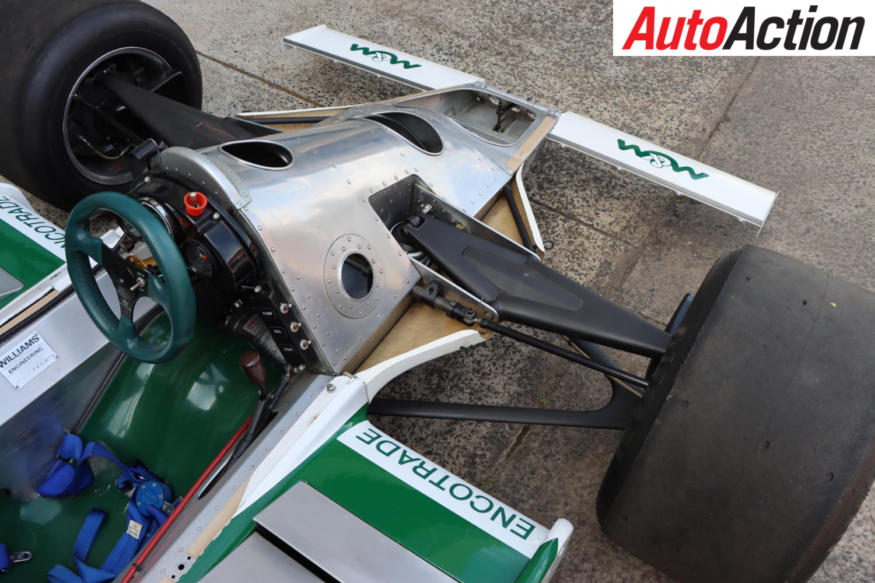

The FW07/04 features a Hewland FGB 400 five-speed transaxle, which remained largely original, save for one part which was easily attainable through the local Hewland agent before the gearbox was resealed, cleaned up and refitted.

The cast magnesium adaptor plate behind the Hewland featuring the oil tank, Desoutter air-starter and clutch slave, remains original.

Due to the high amount of ground-effects produced, the suspension was set-up very stiffly. The design featured front and rear rocker arms working together with inboard spring/damper units.

Brakes were ready to go with new pads and seals, though one of the discs needed to be replaced due to a crack.

Reluctantly rebuilt were the front wings, having been trampled on at some stage, while most the exterior of the FW07/04 remains original. The engine cover was repainted, but the stickers and battle scars remain from when it competed 40-years ago.

Working with Eckersley was a big thrill for Faulkner, as the former Williams number one worked his magic one last time.

“Wayne was great,” Faulkner enthused.

“He did unfortunately have the nickname ‘Wayne the Pain’ in the era because he was so pedantic, but AJ said it to me directly: ‘Yeah, he was annoying to people at the time, but he probably saved his bacon as well when there was uncertainty. They’d go in Wayne’s direction and he’d be right’.

“He was great, he’d be there in the morning. Wayne constantly sent emails to Patrick Head asking him about this or that, and Patrick didn’t know, being 30-years ago. His enthusiasm was unparalleled and the detailed knowledge he had was amazing.

“He was very particular and he’d have amazing knowledge of some detail, he could tell you all these things that no one else would know.

“It was good for Wayne; he’d retired as such and it made his year to relive the glory days. It was great for him.”

Due to FW07/04’s limited use, maintenance is not a problem.

“Because we started with a fresh engine and gearbox, everything is zero life, the maintenance is quite low,” said Faulkner.

“It’s more calendar time … needing to reseal things. I think it’s really only done about six hours of work since rebuild. The engine just requires a change of oil and filter, we’re still on the original set of plugs.

“It’s not such a monstrous thing to get started. Earlier in the year I tried to see if I could do it myself sitting in the car with the starter bottle next to me, cranking the lever and I managed to start it, but I couldn’t drive off because the starter bottle was still connected at the back of the car.

“A real simple car that a backyarder can almost look after. No laptops.

“The hardest thing is getting strapped in! AJ and I agree the car has shrunk over the years!”

Faulkner is full of praise for the drivers of the era, lamenting that technology has overtaken the outcome, which back then was largely determined by the brain in the seat.

“His job was to hand back at the end a stuffed, well used Williams,” Faulkner said.

“They wanted a hard charger, they didn’t want an umm or ahh driver, he (Jones) wrung its neck, that was his job, but (he) brought it home.

“I think back in those days where you didn’t have radios or people back at the factory, it took a lot upstairs to manage a race, any problems you had, you managed yourself. That’s why I admire the drivers of that era a bit more. Don’t get me wrong, modern drivers are great but there was more onus on the driver back then.”

And finally, what happened to the original parts replaced during the restoration?

Well, Faulkner has retained all those, which include the original wiring loom and cracked mirrors, maintaining the FW07/04’s heritage.

Although Faulkner is unable to keep the FW07/04 at home, he has collected a vast array of associated memorabilia including an original Saudi Air Williams jacket and many Tamiya 1/24 kits of the car.

So it’s safe to say, FW07/04 is in good hands.

Auto Action thanks Paul Faulkner for his assistance with this article, which concludes our Alan Jones series celebrating the 40th anniversary of his World Championship triumph.

WILLIAMS FW07/04

ENGINE:

Ford Cosworth DFV 90º V8

Displacement 2993 cc / 182.6 cu in

Bore / Stroke 85.7 mm (3.4 in) / 64.8 mm (2.6 in)

Compression 11.5:1

Fuel feed Lucas Fuel Injection

Lubrication Dry sump

Power 362 kW @ 10,600 rpm

Torque 253 ft lbs @ 9,500 rpm

Fuel tank Marston

DRIVETRAIN:

Hewland FGB 400 5 speed Manual, Borg & Beck clutch

CHASSIS:

Aluminium monocoque

Rims Dymag 13×11 at the front, 13×18 at the rear

SUSPENSION:

Front Top rocker arms, bottom wishbones, inboard springs

Rear Lower wishbones, top rocker arms and links, inboard springs, Koni shocks

BRAKES:

Lockheed ventilated discs, twin-calipers, Ferodo pads

DIMENSIONS:

Weight 579 kg

Wheelbase 2692 mm

Width Front – 1738 mm

Rear – 1600 mm

RACE VICTORIES – Chassis Number FW07/04

1979 German Grand Prix (Alan Jones)

1979 Austrian Grand Prix (Alan Jones)

1979 Canadian Grand Prix (Alan Jones)

1980 Argentine Grand Prix (Alan Jones)