UNDER THE SKIN: HONDA NSX GT3 – INTERNATIONAL RELATIONS

Under The Skin: Honda NSX GT3

If there is a GT3 model on the market that reflects the international nature of the class, it is the Honda NSX GT3. HEATH McALPINE delves Under The Skin into the engineering partnership between JAS Motorsport and US-based Honda Performance Developments

AFTER FIRST being announced in 2016, the Honda/Acura NSX GT3 finally made it to Australian shores for the Bathurst 12 Hour earlier this year in the form of a newly launched Evolution version.

Although the new model failed to finish, the NSX GT3 Evo demonstrated sharp improvement across the weekend. Dane Cameron set the race’s fastest lap to that point, 0.7s faster than its qualifying pace, until electrical gremlins halted the team’s run in the eighth hour having already been delayed earlier in the event.

Yes, it was a disappointing result, but the NSX GT3 is a successful GT3 model in the US where it won the IMSA Weathertech Sportscar Championship last year courtesy of the Meyer Shank Racing team of Mario Farnbacher and Trent Hindman. This was among eight major titles won across Asia, Europe and the US, amassing 17 overall and class victories during the calendar year.

The NSX GT3 was revealed at the 2016 New York Motor Show, but there had been quite a build-up to that point. Originally Italian-based Honda affiliate JAS Motorsport partnered with HRD Sakura to kick off the project, but Honda Performance Developments based in Santa Clara California took over the Japanese manufacturer’s role.

Since then, the Evolution kit was released for the beginning of the 2019 season with improvements focused on aerodynamics and practicality.

HPD has previously provided engines to IndyCar and completed the development on racing prototypes including the DPi chassis that Team Penske campaign in the outright class of the IMSA Weathertech Sportscar Championship.

Engineering partner JAS Motorsport is experienced in touring cars mostly having raced Honda Accords through Super Touring and developed the Euro R for S2000 competition in the World Touring Car Championship. This partnership has extended further into TCR where the Civic Type R is one of the top models in the burgeoning class.

Upon its launch, JAS Motorsport CEO Alessandro Mariani was enthusiastic about its success. He told Auto Action at Bathurst about his push for Honda to enter GT3, which kicked off a new era for the Japanese marque.

“The project, the Honda NSX is a top car in the market so all our competitors are racing in GT3,” Mariani said. “We also like GT3 because in the past we have a relationship with Stephane Ratel and GT3 is an amazing championship between the events worldwide and manufacturers involved.

“For me, it was a good opportunity to keep the brand of Honda at the top of a challenging championship.”

Mariani is also determined to have JAS Motorsport to run a program to oversee any troubleshooting, as the NSX GT3 continues to be developed for serviceability and user-friendliness.

“I push for us to race directly, because it is easier for us to understand directly the problems with the car,” he continued. “It is difficult for the manufacturer to understand because the team is not at the professional level.”

This will occur as Honda will undertake its first full attack on the Intercontinental GT Challenge through JAS with a single-Pro entry. HPD will aid with the program after coordinating much of the development work on the Evo kit, as detailed by Principal Engineer Lee Niffenegger.

“The program actually started in Japan with HRD and then in December 2015 it was transferred to HPD,” Niffenegger told Auto Action. “Honda wanted it for the Acura brand in the US so we took over the development of the car and took it to homologation.

Honda’s American luxury brand Acura had previously used the GT World Challenge America as a development tool for its road cars through programs utilising its Integra, TSX (Accord) and AWD TLX models.

But, with the category’s move towards GT3, both Acura and Cadillac, which entered models not conforming to the new regulations decided to develop new machinery. Cadillac alongside Pratt & Miller built the controversial ATS-V. R GT3 while Acura/Honda entered the NSX GT3.

The Cadillac was described as a prototype by regulation creator Ratel once it had completed its domination in the US. The NSX GT3 on the other hand was and continues to be very much based on the road car, utilising the two key components of any road-going or track machine, the engine and spaceframe.

“All the series are going to GT3 cars, it’s obviously the direction we had to go in, the TLX was sundown and the GT3 car took over in 2017,” Niffenegger reflected.

“Given the timing that we had, they literally had just started doing on-track testing so we took it from that point, so there was very little actual running of the car. It was a complete takeover from that point, some stuff we changed, some stuff we didn’t it just depended on performance and FIA requirements.

“JAS went through the initial development phase with Japan before we took over. They already had probably multiple ideas built up, then we went testing with plenty of trial and error occurring, plus compared notes with us.”

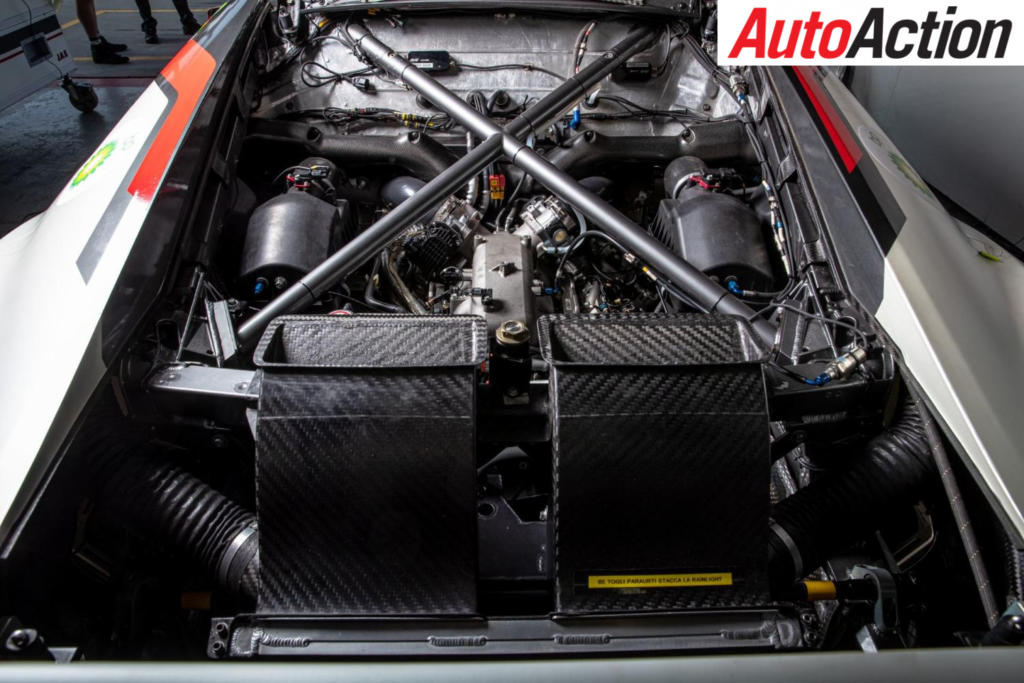

When the original GT3 version was launched in 2016, it was highlighted that there was much corroboration between Honda’s development teams of the road-going and race-spec machine. This continues with the Evo as the HPD team utilise the same 3.5-litre twin-turbocharged V6 unit to power the GT3 built at Anna Engine Plant, Ohio. This is longitudinally mid-mounted.

This part fails to sound particularly challenging, removing the hybrid system that is a fixture of the road-going supercar was, as Niffenegger explained.

“Our car is still very much based on the road car, we use the spaceframe straight off the factory with just some minor modifications, including a cage,” he said.

“The engine itself is straight out of the road car, we get the engines from the factory, they prep them for us. We run now for the latest Evo a European-spec turbo, it’s a little bit different just due to the emission regulations, it can handle higher exhaust temperatures, so good for racing.

“Good for emissions also good for racing in that case, different goals.

“That’s what we changed to in 2019, all we really do is take the road car engine, do some minor machining that the factory guys do for us externally, not internally just to mount alternator [and the] starter that the road car doesn’t have because it’s a hybrid. It’s just external, we don’t touch internals at all from the factory, completely stock.”

This means that the block, heads, valve train, crankshaft, pistons and dry-sump are directly from the road-going engine drawing comparisons to the Civic Type R TCR, which is designed much in the same vein.

“The TCR engine is probably more modified than the GT3, it has a little pan baffle and stuff like that,” Niffenegger remarked. “The NSX is already dry-sumped from the factory so it’s ready to go.”

Although the engine remains the same, there are some parts that have been developed due to the hybrid components being taken away.

“Basically, we take all the hybrid motors out, make a flywheel, then add a starter to the bellhousing adapter and match the Xtrac transmission to it,” Niffenegger explained.

“From the engine side, we just change the wiring harness and similar hoses to motorsport spec so it’s more reliable for a higher temperature environment, high stress running.”

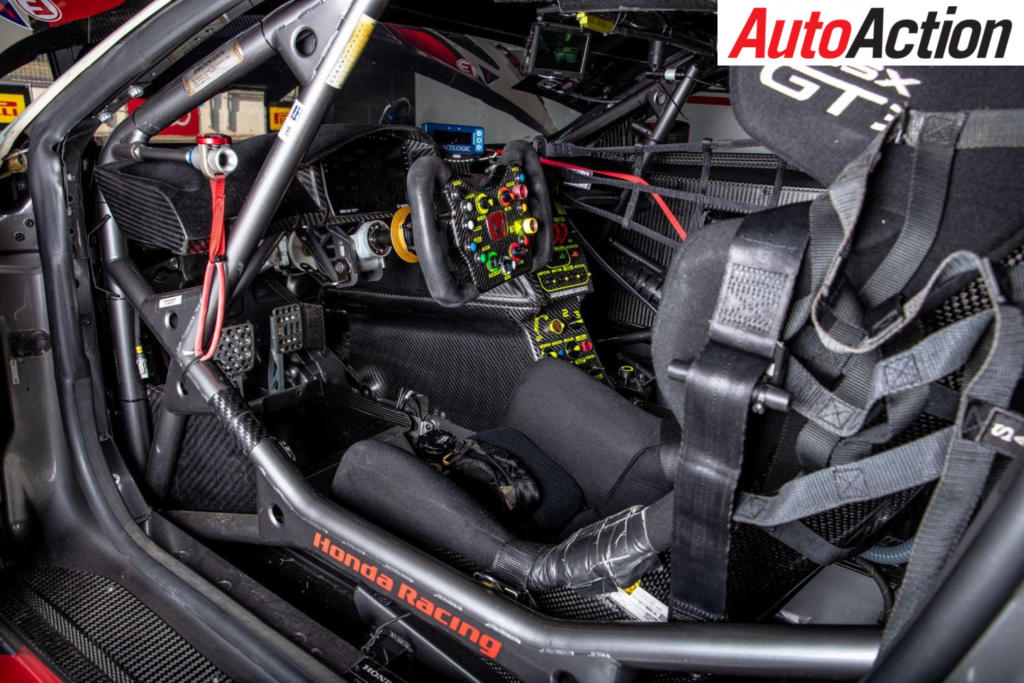

The aforementioned Xtrac six-speed semi-automatic gearbox is worked through paddle shifts on the steering wheel, which is now the trend within any race car interior. The 3-disc sintered clutch is supplied by SACHS, which is electronically assisted through the PANKL double tripod drivetrain.

“We use the Xtrac because it is very similar to a couple of the other cars, just with our ratios,” said Niffenegger. “The project had actually started and they had already chosen Xtrac; from the HPD side we have very good experience with Xtrac, we used it in the TLX GT.

“There was no reason to change it, we knew it was reliable.”

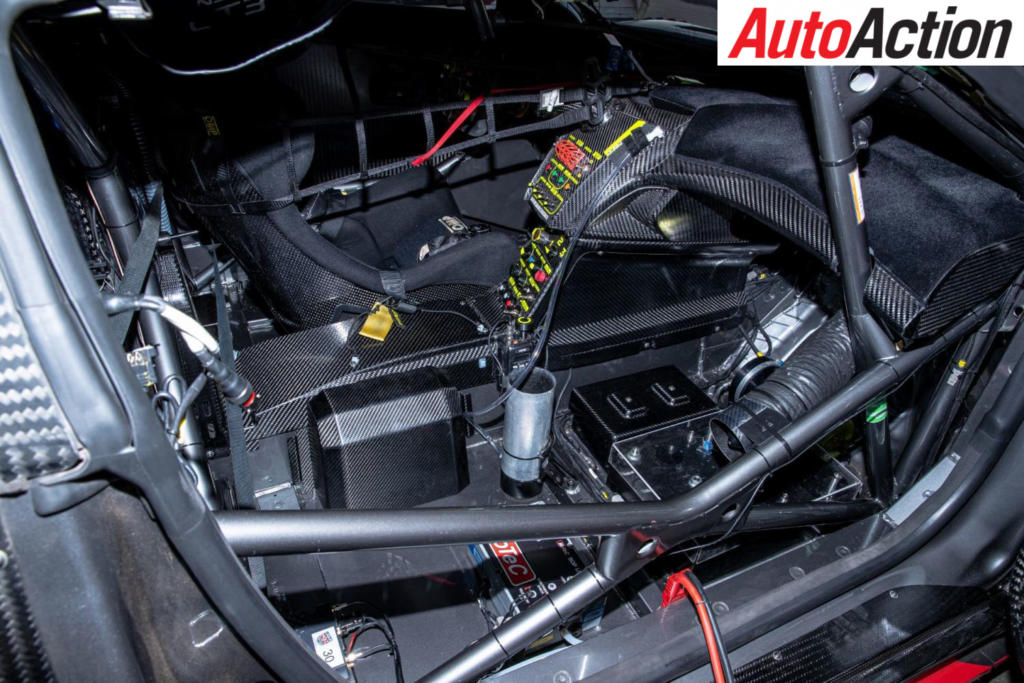

Also, the addition of a larger fuel tank forced the team at HPD to change the layout of the interior, which has had an effect on the method in which the clutch is activated.

“We’ve had to make an enclosure into the cabin, which has created its own set of challenges and knock-on effects,” recalled Niffenegger. “It takes up space that’s normally for the driver, we started out with a three-pedal system, but we ended up going with an e-clutch and pedal system, the clutch is actually operated from the steering wheel.

“It’s just a two-pedal system. It also runs an auto-launch program. It’s really good for gentleman drivers because you don’t have to have that clutch feel from a racing component because we can just tune it to different modes, launch, pit lane whatever.

“That’s was really driven by the need to have enough space for the driver because you can only push the pedal box so far forward.”

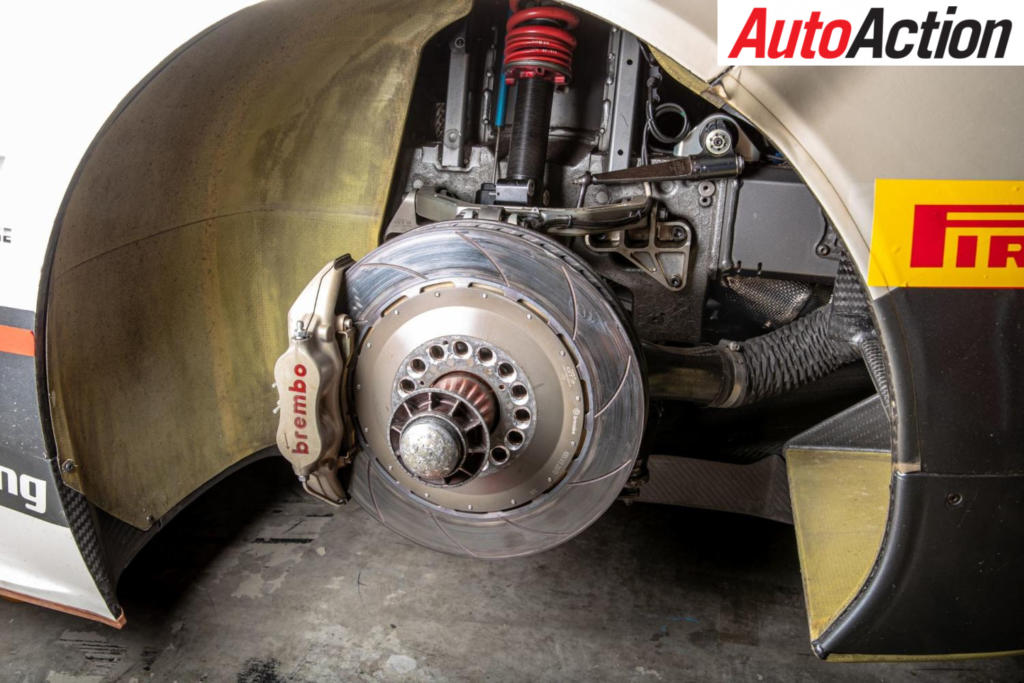

SACHS also provide the 5-way adjustable shock absorbers, which are mated to bespoke suspension components including FR/RR sway bar with adjustable blade. The stock mounting points are utilised with a double-wishbone system at the front and multilink in the rear, but modified to remove the limitations placed on the systems for road application.

“The suspension mount points are the same as the road car, but we make all bespoke suspension parts, it’s the same style, but the race car runs lower, different travels and tweak the geometry,” said Niffenegger.

“Mainly, it’s the same as the road car, we have all the same mount points on the chassis side.”

Brembo provide the braking system with 6-piston callipers at the front mated to 390mmx34mm discs, while 4-piston callipers work together with 355mmx32mm discs to stop at the rear. A Bosch M4 ABS system provides just one of the aids that GT3 models feature to make the category easily accessible to gentlemen racers.

Surrounding the brakes are 12×18” OZ Racing rims at the front and 13×18” at the rear with Pirelli 315/680 – 18 DHD2 tyres at the front and 325/705 – 18 at the rear.

Inside, the clean interior features a multitude of Bosch electronics including DDU8 dashboard display, which is backed up by a C60 data logger and PBX90 power box, while Cosworth provide the ECU. The steering wheel is a bespoke JAS item, but has been developed alongside Italian race equipment manufacturer OMP, which provide the belts while a Sparco floor-mounted seat is utilised.

As previously mentioned, the NSX GT3 features a two-pedal system with the clutch operated through the steering wheel, but the pedal box is also a display of the engineering prowess of JAS as the pedals and mechanisms are developed in-house. The masters are an AP off the shelf product.

Safety was a key agenda for HPD when producing the Evo, going above the FIA regulations to provide peace of mind to its customers starting off with a now essential piece of equipment, the firebomb.

“The firebomb system is an off the shelf OMP item. We’ve been through a couple of manufacturers just based on FIA specifications, then the manufacturer we were using didn’t get certified,” explained Niffenegger

“Safety feature-wise, we do have some extra side impact foam that’s not required by the FIA. It’s been installed based on the experience JAS has with touring cars, but if you look on the roll cage side there are extra energy absorption pads, basically things we thought were important. It’s extra safety for the driver and things that the FIA say is a good idea, it’s not required, but you can do it if you want.

“Unfortunately, we’ve had some big hits, but the drivers have come out of it and said, ‘good job guys, thank you’.”

One main criticism about the first version of the NSX GT3 was the lack of the downforce in the rear, having the flow on effect of scorching the rear tyres. The work completed on the aerodynamics was undertaken by HPD across wind tunnels in the US, Asia and Europe. Aerodynamics is an important feature of the model because it lacks in other areas due to the FIA’s Balance of Performance measures.

“We used wind tunnels from all over the world, there’s one in Japan that belongs to Honda. We use Wind Shear, which is one a lot of car manufacturers use in the US so we correlate all these wind tunnels and depending on what we’re doing or what the purpose we use different tunnels, we’ve used the Sauber wind tunnel for the Formula 1 team, that’s where the FIA does its testing,” revealed Niffenegger.

“Centre of Pressure is one of the things we look at, so we look for a particular characteristic of how the car makes downforce. There are performance windows so the FIA determine the performance of a GT3 car by three categories, engine power, aerodynamics and drag, so they mix them around in different ways and compare.

“Every one of the GT3 cars has to come within those windows, you can choose where you want to be to define the characteristics of the car so that’s your guideline of the design of the model.”

While balancing this aspect of development, HPD was mindful to still produce a user-friendly chassis for its target market of gentlemen drivers. As Niffenegger further elaborated, making the NSX GT3 Evo the optimum racer would not only take away from the gentlemen aspect, but as the category is BoP driven, it is not necessary.

“If you solely focus on a Pro driver going fast then a gentleman driver may not be able to handle it,” Niffenegger illustrated.

“One of the big targets that had to be met especially during the model evolving was not necessarily going for outright performance because this is a BoP series. If your test driver is only making the thing go fast, it’s not going to work out for the junior or gentleman driver.

“One of our other targets of the car was to focus on balance, not necessarily having the slipperiest car.”

Also high on the priority list was serviceability. Honda is renowned for its reliability and market-leading service performance so this had to carry through to its customer racing program, launched in 2018.

Honda are gearing up for a dramatic growth in GT3 in the next year, which has begun with various NSXs racing in Europe and a large presence in Asia. Now we just need one in Australia.

DRIVING THE DEVELOPMENT

TEST AND IMSA Sportscar Championship driver Mario Farnbacher has led development of the Honda NSX GT3, joining the effort in the midst of testing the Evolution kit.

The 27-year-old German is thoroughly experienced when it comes to endurance and GT racing, winning the IMSA Sportscar GTD Championship in the US last year with Meyer-Shank Racing.

Through the development phase Farnbacher identified key areas that needed improvement including the rear tyre life, whilst a focus on useability for a gentleman driver was also a top priority.

“The main problem before the Evo kit was the rear tyres got eaten up due to not enough aero, especially at the rear,” Farnbacher told Auto Action.

“The main change for the Evo kit was basically aero and some small details around the car, which was a huge step forward especially in terms of drivability and overall pace during a stint.”

These cars are made for gentleman drivers as well so we have to keep that in mind, it was one of the reasons why we developed the Evo kit and it has definitely showed some strength around the world where gentleman drivers, plus professional teams, are picking the NSX

“We are really, really proud of this.”

And the strengths of the NSX GT3 Evo? According to Farnbacher, it’s the braking performance.

“It’s really hard to tell because the BoP factor is a big game changer in the end so for sure braking is one of the strengths of this car, you can basically set up the car before braking. Weakness, as soon as we get some weight in the car it doesn’t perform so well.”

TECH SPECS

CHASSIS

Aluminium alloy extruded profiles/cast nodes, roof structure in steel, TIG welded roll cage in 25CrMo – bolted to chassis

ENGINE

Twin-turbocharged DOHC V6/75°, 3501cc, Light alloy block and head, cast aluminium pistons, 24 valve, IN/EX VTC, chain-driven camshaft, direct and port fuel injection, dry-sump system, drive-by-Wire throttle system, electric wastegate control, 2 Off – Mono Scroll turbocharger, Twin Pipe with CAT converter

Layout: Longitudinal/mid-mounted

Bore x stroke: 91 x 90 mm

TRANSMISSION

Gearbox: XTRAC semi-automatic 6-speed sequential, ZF/SACHS high performance sintered or carbon clutch (endurance option), electrically assisted, PANKL double tripod system driveline

SUSPENSION

Front: Double wishbone

Rear: Multilink

SACHS 5-way adjustable dampers shock absorbers, FR/RR with adjustable blade sway bar

BRAKES

BREMBO disks 390×34 front / 355×32 rear, BREMBO 6 piston front calipers /4 piston rear calipers, BOSCH M4 ABS system

WHEELS

Front: 12”x18” OZ forged aluminium

Rear: 13”x18” OZ forged aluminium

DIMENSIONS

Wheelbase: 2630 mm

Overall length: 4612 mm

Overall width: 2040 mm

Front track: 1715 mm

Rear track: 1687 mm

Weight: 1240 Kg

Article originally published in Issue 1783 of Auto Action.

For Auto Action’s latest feature, pick up the latest issue of the magazine, on sale now. Also make sure you follow us on social media Facebook, Twitter, Instagram or our weekly email newsletter for all the latest updates between issues.