UNDER THE SKIN: RADICAL – OPEN WIDE AND SAY ‘RRRR’

Under the Skin of a Radical

Radical has been one of the success stories in one-make racing around the world and Radical Australia offers a complete racing experience, for everyone from novices to experts

Radical Race Car

IT WOULD come as no surprise to anyone who follows motorsport which company is the world’s biggest manufacturer of racing cars.

No; not Dallara. Or Tatuus, which is in a lot of open-wheeler markets. Or Elfin (though, at one stage, it was).

It’s Porsche.

Of course it is. The Stuttgarteers might have made 237,778 road cars last year but along the way it made quite a few 911 RSRs, GT3 Rs and GT3 Cups and Cayman GT4 Clubsports.

Second biggest? Radical.

Now that would be a surprise. The business in the north in England has been around for 20 years; in that time it has made more than 2000 cars, most of them for the track. Along the way it has branched out to all corners of the motor racing globe, including this corner.

Radicals are the obvious extension of what came before in British motorsport; at Lotus and, before that, at Cooper. It takes modern engine technology – in this case, motorcycle engine technology – and puts it on the racetrack as simply and inexpensively as can be done.

It all started in 1996. Two club level racers in the UK, Mick Hyde and Phil Abbott, between them came up with the idea of putting a modern four-cylinder motorcycle motor in a racecar. Abbott, an engineer, worked on the technical concept; Hyde’s background was in marketing. Nick Walford designed the original car, which was quite competitive when it hit the track.

Another came along for Hyde; they were allowed to race within their own class against Sports 2000s, a class that caters for 2-litre FFord-powered cars with sporty bodywork. When they started winning, people took notice…

Radical on track at Sydney Motorsport Park

By the time Radicals got their own series in 1999, there were 27 of them on the grid. The rest, as they say, is history…

In late 2011, Hyde sold his stake in the company. In May 2016 Abbott left, and a new management team, headed by CEO Joseph Anwyll, took over. Shareholders are now Andreas Zielke, a former automotive architect and now movie producer and hotelier, and Jan Osterloh, with former Lotus man Duncan Johnston taking the role of Sales Director. There are 130 staff and up to 12 Radicals roll out of the factory every month.

The cars have been in Australia for more than a decade.

“We brought in five cars ourselves in 2005 and we became the distributors in 2006,” Radical Australia’s Chris Medland explains.

“A part of the plan was, we ran a corporate entertainment business and we ran the Radicals in Drive Days. It just got bigger and bigger – and we had bought way more cars than the previous distributor had sold! So it just made sense really.

“We started racing in 2006. I don’t think any of us even had CAMS licence. We started racing in 2009, as a part of the New South Wales CAMS Series, and in 2010 we got our own slot.”

Behind the wheel of a Radical

Radical Australia offers three levels of involvement for customers. The Radical Australia Cup (RAC) is running over five rounds, three in the Shannons Series, catering for the SR3. The second tier is the Radical SuperSport Series, which opens up the competition to other cars – including Radical’s own SR8. Three of the five rounds are at Sydney Motorsport Park, the other two being Wakefield Park and Phillip Island.

At the third tier, Radical promotes Track Days at SMP, to allow rookie drivers to become familiar with the sport, without the pressure of competition, if that is what they want. There will be 12 of those days throughout the year.

“Radical is a complete package, which is a big part of its success,” explained Radical Australia’s Greg Smith, who has himself progressed from a ‘track day’ racer to a contender in the RAC.

“It’s a tiered program which caters for both amateurs and experienced competitors alike. The ARDC track days are an ideal, low pressure way for drivers to get miles and experience the whole Radical program.

“Being based at Sydney Motorsport Park, our team is there to assist in every way, and with our driver lounge, dedicated pits and technical crew on site, drivers have everything they need to compete at their level of comfort.

“For those that are serious, we have driver coaches and engineers available to help them go quicker – something for which the dual seats in the Radical is invaluable – and as they progress, we can assist them to compete in the SuperSport Series and ultimately Radical Australia Cup, and if they so desire, we can also support them to compete overseas, just as each year’s RAC champion does as part of the European Championship.

“It’s a fantastic package that lays the foundations for drivers who may have found motorsport a little later in their careers, or as a stepping stone to compete at a higher level in Sportcars, which we’re proud to have seen a number of our drivers do in recent years, something we expect to see more of in 2017!”

Radical SR3 RSX at the Race Of Champions

Radical started making its current car, the SR3, in 2001. Last year it made its 1000th example of the model – which apart from racing in such far-flung places as Canada and Saudi Arabia (imagine the different cooling parameters) have been used in the annual Race of Champions event. So yes, Sebastian Vettel has raced a Radical…

“In the first Bathurst, and they our most popular rounds, we have 25-28 cars. Maybe 22 in New Zealand – they are very popular rounds,” says Medland.

“But at Sandown recently, we had 16 cars; it was school holidays, a busy time, and it is difficult to get dates that suit a lot of people.

“We have sold 80 cars – and there are another 10 or more that people have imported by themselves, separately. So there are nearly 100 cars in the country.”

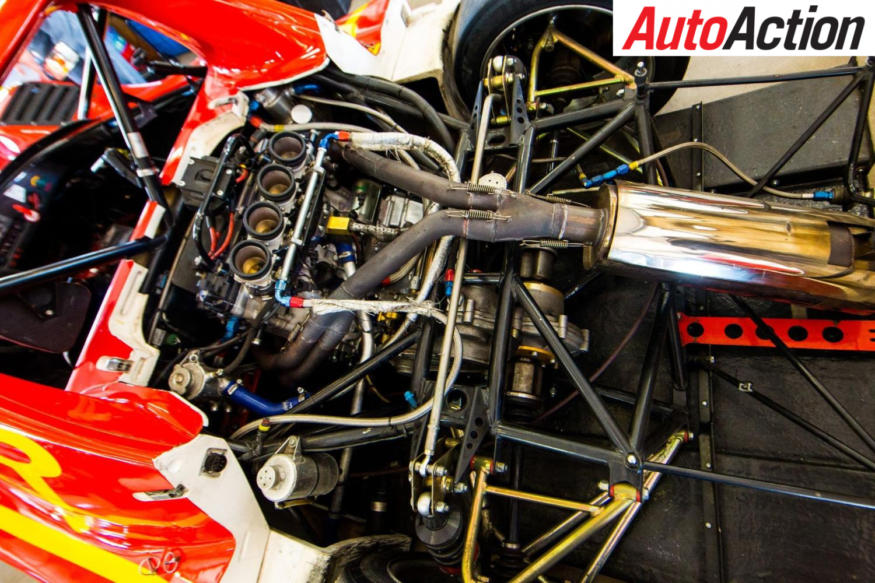

The cars are built around a spaceframe – which does sound a bit unexciting in 2017. Far less dull is that the chassis incorporates an integral safety cell in its design, including a deformable aluminium honeycomb front structure and collapsible steering column. For all of its mid-20th century technology – which is easily and inexpensively repairable –

Radical points out that the SR3’s torsional strength approaches that of some equivalent carbon fibre designs.

One thing that has improved over the journey is the presentation of the cars. When the early examples arrived the bodywork was a bit… rustic.

“They have done a terrific job,” says Medland. “When we started the looked a bit like a ‘kit car’; the panels were unfinished, they did not have a livery. They didn’t quite have the look, they were a bit like a modern Lotus 7. To Radical’s credit, they learned to make them look like models; now, as delivered, the look terrific.”

So now there is ‘showroom appeal’ right from the get-go…

The Radical’s suspension package

Front and rear suspension is bespoke to the SR3. Springs and dampers are built to Radical’s design by Intrax, and the design features unequal-length double wishbones, attached to pushrod-operated rockers in use front and rear. This is where things get a bit clever…

The system incorporates an anti-roll link by having the lower wishbone attached to a pushrod that operates the rocker. That ‘Nik-Link’ bar, so named after design chief Walford, acts on the opposite wheel’s lower wishbone, effectively fulfilling the role of an anti-roll bar. Roll stiffness can be changed as easily as changing to a stiffer or softer bar, and the simple design has been rolled out to all of Radical’s SR-series cars.

Transmission is by long-time Radical partner Quaife. The original SR3 came with largely standard six-speed sequential Suzuki transmission, and there was a somewhat rudimentary chain-drive arrangement to a transmission. But since 2009 there has been a ‘proper’ gear-driven unit in place, complete with optional pneumatic gear-shift with steering wheel-mounted paddles. That allows flat-changes on up-shifts and incorporates an auto-blip system that matches RPM on down-shifts, so the clutch is required only when accelerating from standstill.

The SR3 has it own instrument display featuring LED analogue RPM counter, gear indicator, shift light and four LCD displays for engine parameters and speed.

Radical designs its own centre-lock, one-piece cast aluminium wheels, which have passed Germany’s strict TüV standards – which are meant for items designed for road cars. That is because, with few modifications, a Radical can be road registered in many EU countries, as well as the UK.

Radicals are based around a motorcycle engine

Of course the very basis of the car was to build a racer around motorcycle engine. Suzuki’s introduced the Hayabusa (or GSXR1300, if you must) in 1999, in doing so, resetting the performance parameters of road-going motorcycles. At 1299cc, the original motor produced 129kW and gave the bike a top speed of 299kmh – a maximum that was largely set there to avoid any negative publicity surrounding selling a 300-plus kmh bike to the public…

Since the original motor Radical has developed its own version, called the Powertec. It still maintains Suzuki’s architecture – DOHC, four valves, dry sump, with remote oil reservoir and oil cooler – but both versions have been upgraded. The 1.3-litre Powertec is rated at 156kW and the 1.5-litre – which is what is raced in Australia – now cranks out 194kW.

And now for something completely different, in motor racing anyway… the engines come with a warranty. For 40 hours use, or 12 months (whichever comes first) and provided that the owner strictly abides by the use of the stipulated oil (Fuchs) and rev limits (10,500rpm; hit 11,250rpm and the deal is off) Radical will rebuild your motor if it breaks. That is showing a lot of faith in the product.

“We did have a problem with engines,” says Medland.

“With the 40-hour warranty on the engines and we used to have to send the engines to England to be refreshed. It was only five years ago that we became only the second, ratified engine workshop outside the UK. The other one is in the USA.

“We get a factory technician come out every year to talk to our engine people and that has been a great help.”

In 2009 the SR3 underwent substantial aerodynamic upgrades. New front bodywork incorporated a higher nose, which ducted air to the front brakes for cooling. The venturi-style central section of the splitter created significant additional downforce, with the air passing under the wing extracted by louvered vents on top of the front wheel arches.

A vertical wing was incorporated into the side radiators’ air intakes, to smooth airflow, and side skirts improves stability in high-speed yaw (sideways) movements.

Out the back, a bi-plane rear wing is available in either aluminium or optional carbon fibre, with a composite construction rear diffuser available for additional downforce.

The drive train and rear diffuser

For 2017, there is another update. Oliver Smith finished third in the 2015 RAC, then second last year, and has updated to a newer SR3RSX for 2017. The new car features updated bodywork, improved aero and a new ‘Gen 4’ long-stroke engine.

“It delivers more torque down low,” says Medland. “The other engine was very ‘revvy’; a bit like a go-kart. The big change is the aero; there will be a lot more on the new cars. They are more tunable; the new one will be sensitive to 2mm ride-height changes.

“That is part of the evolution of the drivers; before they were all-out, right away, but now they are a lot more in tune with what the car wants. We used to offer race coaching to all of our drivers; now there are only a couple of driver coaches who are better than our front-runners.

“The times are very close. At SMP recently there was 1.5s over first to 10th, and for an amateur race series, that is pretty good. We support whatever the drivers want to do and we have a Track Day every month at SMP. If they just want Track Days, that’s great; some want to use it as a Practice session for the next race.”

With nearly 100 customers to support there is a big commitment to providing service – but Radical is still a business that has to be profitable.

“We are not Porsche; we can’t have a semi-trailer full of parts ready,” said Medland.

“The spare parts thing is very difficult. It takes ages to get parts out of the UK. It is, as you say, nearly 100 cars, but you have to run it lean. Getting the right balance of having sufficient parts in stock, without having to air-freight everything in, is very hard.”

But with large fields, of nearly identical cars, it is rare that one hears that a competitor gets stranded because they can’t fix their Radical.

The bottom line is that the category provides good bang for the racers’ buck.

“Most of our front-running guys would spend $80,000 a year, which is very good value,” says Medland.

“They own the cars. Some do private leases; when we are in NZ this year, there is only a week before Challenge Bathurst. Some will be leasing cars for that event.”

So you can drive a racing car at Bathurst – and across the ditch at Highlands – for not a lot of money. Or, you can have a Track Day car that offers a pleasing speed-for-dollars ratio – even keep it at a racetrack – for not more than one of the teenagers keeping a horse. Or two (they only ever seem to come in eight-legged lots).

All in all, racing Radicals was not a terrible idea, from two blokes who went club racing 20 years ago…

TECH SPECS

Radical SR3

Engine: Suzuki Hyabusa-based Powertec DOHC four-cylinder

Capacity: 1500cc

Power: 194kW

Max Revs: 10,500rpm

Body: High down force, lightweight fibreglass bodywork

Dimensions:

Length: 4077 mm

Width: 1799 mm

Height: 1093 mm

Weight: 570kg

Gearbox: Quaife 6-speed

Paddle shift

Brakes: Radical four-spot callipers on 280mm rotors

Suspension:

Front and Rear unequal length wishbones

Fully adjustable ‘Nik-link’, fabricated uprights, forged centre locked hubs

Choice of bespoke Intrax fully adjustable dampers

Wheels: Radical centre lock, cast aluminium

F: 8″ × 15″

R: 10.5″ × 16″

Data Logger: AIM MXL2 display unit with LED rev counter, gear indicator, shift light

Fuel system: Aluminium, foam filled 77-litre fuel tank

By PHIL BRANAGAN

Article originally published in Issue 1717 of Auto Action.

For our latest Under The Skin feature pick up the next issue of Auto Action Magazine, on sale Thursday. In the meantime follow us on social media Facebook, Twitter, Instagram or sign up for our weekly email newsletter for all the latest updates.