UNDER THE SKIN: MARC FORD FOCUS

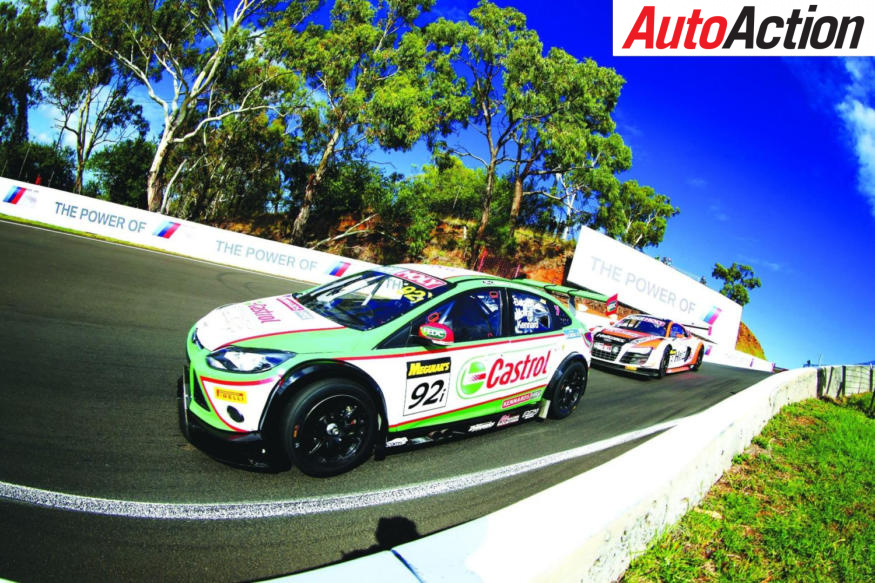

When a Ford Focus appeared in a GT race some people scratched their heads and wondered why. Now there are a dozen of them, and MARC cars has truly earned its place in endurance races, right around the world

IF YOU are a fan of GT racing, 2016 is turning out to be a great year.

It seems that anywhere you look, there are some of the world’s most exotic cars fighting it out on the racetracks – Ferraris, BMWs, McLaren, Audis, Bentleys, Lamborghinis and, of course, a lot of Ford Focuses.

Among that company, the Focuses, and the odd Mazda 3, may be the smartest cars of the lot. The Aussie-developed MARC Cars have made their, er, mark in GT racing and the thinking behind them shows that there are more than one way to go racing against expensive opposition – particularly if you have a good think about things first.

The cars are the product of some clever thinking by designer Paul Ceprnich and Racer Industries boss Ryan McLeod. MARC Cars – McLeod Auto Racing Competition – came about because McLeod saw some limitations in what he was racing a handful of years ago. What started off as a Production Class Holden Astra became more modified as races came and went, which set his mind to a new, simple and robust car.

“For what started out as a replacement for our Astra… That is how it started,” he says.

“That car was built here at Norwell, it was kind of pushed out of its class and I bought it off Holden. We raced it with my Dad and my brother and when we looked at the rules at somewhere like Dubai, there was so much more stuff on the car that we could change. We thought that we would build one particularly for 24 Hour races – and then we realised that we didn’t have enough car underneath us. I didn’t have money to afford to buy a GT3 car so we thought, ‘We’ll build our own!’

“Then the car that Paul Ceprnich penned out came along.”

That car, thought out by the South African-born, Yatala, Queensland-based head of Pace Innovations, was a good idea. In early 2014 the new Global Touring Cars initiative was launched, taking good ideas from various, bespoke Touring Car Series around the world and combining them into a low-cost package, built around a nice, loud V8 motor. That idea – to offer, effectively, a turn-key Saloon Car series – was met with some acclaim but has not quite lived up to the ‘Global’ part of the moniker.

In fact, despite plans to start racing in 2014, the inaugural series in South Africa started only last month at Zwartkops, with five other rounds to follow before the series wraps up in December. With the GTC class attracting only eight entries for the first year (four BMW 2-Series, two Audi A3s and two VWs) the series has had to be ‘topped up’ with the addition of a GTC Production class, for smaller, slower and cheaper Production cars.

The other major change is that the class’s original V8 engine has been set aside and replaced with bespoke 325kW turbocharged fours.

Not in Australia. MARC Cars roll with the full 500hp Ford Coyote V8 engine, driving through an Albins ST6 transaxle.

“We had a list of things we wanted,” McLeod says.

“We had been racing in 24 Hour races for some time, there was no real development of an endurance car in Australia. We saw that overseas, so we started a checklist of things that we wanted to change. When we made a change to our Astra you were kicking the can down the road, so with this, we started at the start.

“Our aim was to have a car that would do two 24 Hour races with the same mechanicals. That would mean that, financially, we could afford to run overseas. The car was running at a low percentage of its capacity. The parts on the car can run THREE 24 Hour races.

“We didn’t start out to build a 24 Hour car. They started out as a prototype for the GTC Series, being raced in Africa, but they were built here. We were helping to put the prototype car together, and we picked the best parts out of that, to go into the endurance cars. We upgraded a lot of things and the car has changed a bit since, but we now have pretty much frozen them.

The ‘A’ car has all the same mechanical parts on it as the ‘K’ car except that they are left-hand-drive, but even that is not a massive change. The chassis allows us to use all the same equipment; the engines are in the same spot, so it is not hard to do that.”

The ‘A’ and ‘K’ references identify individual cars, which have letters and names, not numbers.

“We have seven cars in Australia, and they all have chassis names; Amaroo, which usually runs as #91, it was new for Bathurst in 2014; B for Bathurst is owned by James Kaye; C is Catalunya, owned by Jake Camilleri and sold to Mick Taunton; D is for Daytona, which runs the Donut King livery; F is the car that was destroyed at Bathurst; G is Goodwood, which is the Jake Camilleri Mazda; H is Hockenheim, driven by Jack Smith in the Trophy Series; I is Imola, in the Netherlands, a LHD Mazda owned by Ivor Breukers; J is Jerez and K is Kyalami and they have been sold to VDS Adventures Racing in Belgium, one in the Belcar Series and one in the Creventic Series.

A, B and C are the most widely-raced cars. We have raced Belgium, the Netherlands, the Czech Republic, the UK, France, Spain, by the end of this year in Malaysia and Australia. We haven’t yet raced in New Zealand!

“Earlier this year we raced the same car in four different categories, in three different states over three consecutive weekends.”

McLeod also points out that the car has proven to be easily adaptable to different brands of tyres, and in one two-week period, raced on three different tyre brands – and did so competitively.

The off-the-shelf parts list of the car is extensive, and the philosophy of putting the work into the initial chassis, so that ‘standard’ parts can be easily and cheaply sourced, and fitted without any great modification, works and works well.

“I wanted parts that, coming from Supercars, over the years, we had experience at Faulkner’s, at NEMO (Paul Morris Motorsport) and we could see this part that was modified to do that, and just that, and only one bloke could modify that part. I didn’t want our car to be like that,” says McLeod.

“When you put a MARC car together, you can fit a standard oil cooler, off the shelf here at Racer Industries. You can screw a standard fitting into it, and bolt it into the car without having to modify it at all. We made the CAR the bespoke item, so the parts fit without modification. You can get a part overseas, or take out a spare, and fit it straight away.

“We use the same coolers at the front of the car as at the rear, for the transaxle. Even down to the nuts and bolts, we used standard bolts you can buy just down the street. When it came to the ABS system we used the system from Bosch, in its totality. We made the uprights to accept those fittings, off the shelf, and we fitted it in the workshop in the days before we shipped the car off to its first race at Zolder – and lucky we did, because it chucked down rain all the time! It would have been tricky not to have it.”

One of the clever features of the car is the fuel system. To look at, there is one hose going into the tank and one going out.

“The fuel system has some of the most bespoke parts in it,” McLeod explains.

“Safety was paramount and so was redundancy. The parity of the races overseas, how they work out the parity is by fuel allocation. We get the maximum amount, 120 litres. We wanted to be able to use all of that, and I didn’t want to have to have all fittings and tanks, and filters and hoses.

“We drew from what manufacturers are doing with their OEM and all of the items live within the fuel tank. There is a fuel hose through the car that runs to the engine rail. It has a hose from the filler – which we mount to the chassis, not to the body, so the hose does not get ripped off the car in the event of an accident. Inside the tanks are two pressure pumps, lift pumps and so on, everything you need.”

Then there is the suspension, with mirror-images parts on all corners, which means that the parts are interchangeable, spares are kept to a minimum and there is an unexpected bonus in making the car easy to drive.

“Whether by design or otherwise, when you design a car with the same uprights and suspension components front and rear, same uprights and shocks, you end up with a car that runs nearly the same roll centre front and rear,” McLeod explains.

“That gives the car a really stable and controllable feeling. A normal car might have the front roll centre under the floor and the rear up to 180mm off the ground, and this car feels quite different. Very neutral and controllable. That is the design of the suspension system.

“As time has gone on, we changed the design of the rear control arms, because we wanted something that performed better in an accident. One arm is different, you can unbolt the arm and swap a few brackets around, and bolt it onto the front. Or, left to right. If one gets damaged, you can keep going.”

“In its basic design I thought it was quite clever but there were some things we saw that needed to be adapted. But the basic design was quite robust.

“We changed the fuel system completely, the seating was too, to incorporate the latest from Recaro, with adjustability. We changed some of the aerodynamics, if you look at the first images of the prototype car.

“We changed about a dozen tubes in the chassis, but they were more updates than changes. We changed the wheel spindles, different coolers and so on.”

And the engine remains a Ford Coyote V8, which is quickly becoming one of the most impressive units in motorsport.

“The engine, it’s pretty Australian to have a V8 in there, isn’t it?” McLeod says.

“It has been remarkably simple, it is not an exercise in wizardry. From the get-go, Ford Performance has designed an engine, because it was going into the Mustang, with racing in mind. It is an absolutely fantastic engine, it’s like two little four-cylinder engines put together. It performs flawlessly; we have had no engine failure, other than losing an oil hose and driving an engine for a few laps with no oil in it.

“We pulled the first one down at 6000km. There were no signs of wear, so we put it back together and pulled it down again at 8000km. Then we put in a new timing chain, and ran it to 12,000 kays. That is how we run them now, and we put in a timing chain at 6000. We have never had an engine lose one of those.

“Out of the box, we put in a set of pistons and top-end gear, which you could probably get away with not doing anyway. At 12,000km, a new timing chain and pistons and some moving parts in the cylinder heads, put it back together again for another 12,000km. That’s about $1 a kilometre. It’s very effective, with 530 horsepower, whether at Silverstone at three degrees in the pouring rain with an air filter half-clogged, two months later at Barcelona, 45 ambient in a sand storm!”

At the opposite end of the car is the transmission, which is familiar to anyone who looks at a Supercar. Albins’s ST6 transaxle may have had some teething problems in its adaptation to road racing but McLeod settled on the unit very quickly.

“Albins was always a feature. Those guys had a crack at adapting their off-road technology to V8 Supercars and did a bloody good job at it. I have this belief that you can achieve good things when you have good people around you. Albins stood behind their product and have been quick to update anything if there has been a problem. We wanted something in our cars that would do 7000 kilometres, with an oil change in the middle. That’s two 24 Hour races. Most people would say, ‘You can’t do that’. But they worked with us, it has good adjustability and the shifting is beautiful.

“We have automated downshift, which we have worked with MoTec to perfect, and full-throttle upshift as well. Basically, everything past the engine, Albins have designed – spindles, axles, all the driveline components.

“MoTec have been great as well. We took their M150 in its infancy and they had a watered-down version of that in V8 Supercars.

We said, ‘We want the hamburger with the lot!’ We wanted traction control, anti-lock, good fuel efficiency, electronic throttle and steering, ABS, data logging, fuel modelling – and then put all that across 18 engines. They stepped right up, and the system on the car integrates perfectly.”

With a dozen cars built in batches of three, and customers like John Goodacre stepping up, the golden question is, how much?

“An endurance car is $230,000, drive one out of the door at Norwell, after 13 weeks to build,” says McLeod.

“There are some options – it makes no difference whether it is left or right-hand driver. We could also build a sprint spec, but we haven’t done that yet. You could save some money on the fuel system, we could swap some components for lighter ones.”

A good idea, whose time has come. There may be some new bodywork on upcoming MARC Cars (McLeod says he would like to do a Holden Cruze, but is not sure whether Holden fans would appreciate the Coyote engine) but the basic recipe looks set to stay as it is, for good reason.

THE VIEW FROM THE UK

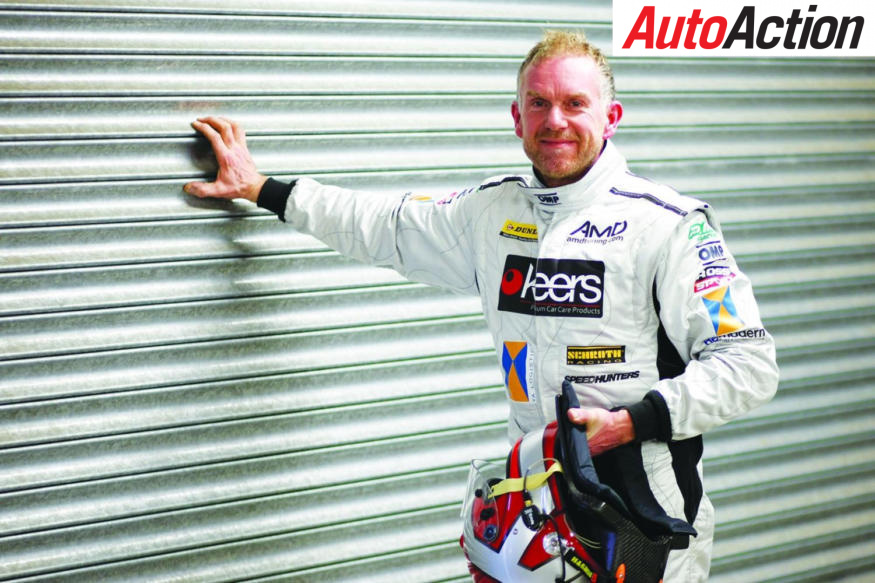

After stints in the BTCC as both a factory driver and a Privateer, James Kaye is well qualified to comment on what works and what does not – and the veteran driver is a big fan of MARC Cars.

“I have been working with Ryan for the last five years,” he told AA, “originally with his Holden Astra, and then I was involved from the very first race that the MARC car did in Europe, at Zandvoort in 2014. When Ryan originally told me what he was going to do I thought he had gone ever so slightly mad! But he and the car have proved us all wrong and it has been a pleasure to be involved.

“In fact Ryan is so persuasive I ended up owning car 92 (named ‘Bathurst’, and the most successful of all the cars so far).

“Having only raced front-wheel-drive Touring Cars for the last 25 years, I had no idea what to expect when I first sat in a car at Zandvoort – it frightened the life out of me when they started the engine! I was well out of my comfort zone. Ryan just tapped me on the helmet and told me to get on with it, as I was the team’s professional!

“What a car to drive. It does everything it should do without any drama – a huge surprise. Don’t forget, these cars had done zero testing and only one race before they were put in a container and shipped to Europe.

“Everything just felt right with the car from the very start. All that was needed were refinements to the original spec.

“Ryan and his team have designed a car that appeals to all drivers because it has no vices and the more you put in the more it gives back – perfect for a multi-driver long distance event where the car has to be easy to drive and adaptable otherwise someone ends up binning it and spoiling everyone’s race.

“It is easy to set up on different makes of tyres and always very kind on them. That, along with the best brakes I have ever driven with, make the car 100 percent the correct thing for Endurance racing.

“You could make the car faster and more knife-edge, but what’s the point? You would just end up with DNFs and very upset drivers.

“The reliability has been the most impressive thing about the car. That’s a huge credit to Ryan and the team.”

MARC Pilots

Some of the drivers who have raced the MARC cars are;

Steve Owen

Dean Fiore

Jake Camilleri

Keith Kassulke

Scott Nicholas

Lyndsay Kearns

Garry Jacobson

Chris Pither

Grant Denyer

Bryce Fullwood

Nick Rowe

Adam Gowans

Gerard McLeod

Jimmy Vernon

Duvashen Padayachee

Paul Morris

Beric Lynton

Max Twigg

Tony Karanfilovski

Andy Miedecke

Mal Nial

Clint Harvey

Ben Gersekowski

Bruce Williams

Hadrian Morral

Mark Griffith

Tony Alford

Peter Leemhuis

Mark Lemmer

Tom Onslow-Cole