Speedflow. High performance products for your car

By Jason Crowe

From small beginnings Speedflow has moved onto the sport’s largest stages – right around the world

There are two automotive icons in Taree. One is the ‘Big Oyster’ that sits atop a local car dealership and the other? Speedflow.

Speedflow was founded by Barry Garside in 1983 from a garage in Marrickville, Sydney.

Back in the 1970s, Barry’s background was boat racing and out of necessity began making fittings for his own equipment while working at an engineering company. Such was the quality of Barry’s craftsmanship it led to fellow racers asking for his components. This quickly created a solid demand so Barry started a hydraulic company which evolved into Speedflow Products.

The company moved to Taree on the NSW Mid North Coast in the late 80s and new premises were purpose built for a small range of machinery to produce all the fittings in house.

These days Speedflow is a family affair, with the Liefting family running the show. Nick, Carol, Shaun and Travis Liefting having been involved with distributing the Speedflow product since the early ’80s from the family speed shop in Auckland, New Zealand.

Speedflow’s Marketing Manager Travis Liefting explains.

“Nick started working in Taree in the late ’90s and had an opportunity to purchase shares in the business,” he said.

“This partnership culminated with the outright purchase of the business in 2010. Since then we have continued to grow the business into the future.

“Our family have a long history in Drag Racing. Nick raced in the ’60s, ’70s and ’80s and now Shaun, Travis and Nick’s granddaughter, nine-year-old Charlotte, are currently involved in drag racing.”

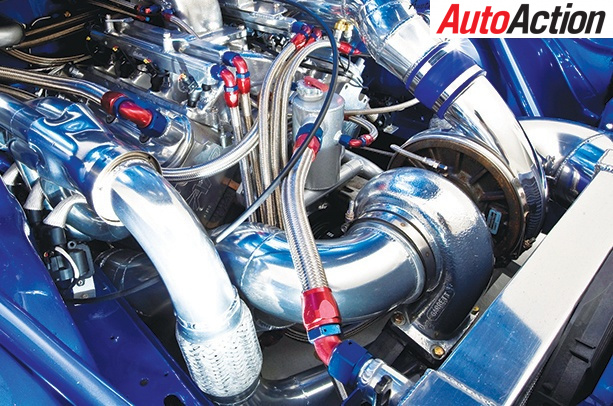

Speedflow products are unique, due to the one-piece formed bends and have a smooth radial flow that is stronger and more compact than their competitors. This manufacturing process allows for a superior fit and finish and, most importantly, reliability under extreme conditions.

These robust, full-flow fittings are not made the conventional way by brazing, but are bent in specialised equipment to produce a compact, solid, one-piece bend, which is as low and strong as a forged fitting but with the advantage of a swept full flow bend.

All other components are made from billet material. Speedflow use no castings or forging which means there are no hidden flaws, resulting in an appealing billet finish.

All processes from machining to packaging are done from the factory to provide absolute control of every product through the entire process. Speedflow’s skilled staff is an important asset, all of whom are local residents, some with 20 plus years of service.

“We anodise all of our own products using a specialised hard coat anodising system for extra hard-wearing properties and we are able to apply a decorative colour,” said Liefting. “All other companies will use a decorative coat process, which does not provide the same level of protection, compared to our hard coat system.

“We also provide custom anodising for any part in our range and now include our Black Series as a standard colour option.”

Speedflow’s steel range of fittings are plated with the Electroless Nickel Process, which offers a highly durable uniform coating providing a bright finish, high degree of corrosion resistance and a degree of lubricity to reduce galling problems associated with stainless steel.

“Our 400m² sales and distribution centre is now completed, with dedicated storage for all our completed fittings, our entire hose stocks and raw aluminium stocks. This has allowed us to separate our sales and production offices to further improve efficiencies.”

The Speedflow name has become synonymous with quality and performance in the hose fitting industry. Its products are used in every facet of motorsport, from the professionals through to the weekend racer, as well as other areas of the market such as the show car circuit, marine, industrial hydraulics and even the aviation sector.

From its Taree factory, Speedflow has been supplying products to the motorsport industry not only in Australia, but have extended their availability to the UK, France, Italy, the Middle East, New Zealand, Indonesia and the USA.

“Speedflow has invested in the latest technology with some of the most sophisticated CNC machinery, including manufacturing CNC lathes of our own design specifically suited to producing top quality products,” says Liefting.

“We now have in excess of 25 CNC machines as well as cutting-edge anodising equipment, polishing machines and a host of other ancillary equipment required to manufacture the best quality fittings available.”

If you are or have been involved in motorsport, chances are you have used a Speedflow component somewhere on your vehicle. Here at Auto Action we support local manufacturing and innovation related to the motorsport industry and like to shine a light on the companies that provide the very best service in their field while providing local employment. Speedflow is one of those companies.

Visit Speedflow’s website on at www.speedflow.com.au to see their extensive range of performance parts and to download their catalogue.