Albins: Australia’s own race proven transmissions

By Jason Crowe

From a humble Victorian HQ, Albins has set its sights on the global motorsport market – and it is getting there, one ratio at a time

Victoria’s Central Highlands is not, perhaps, where one might expect to find world-leading motorsport technology but no one ever mentioned that to Ivan Albins.

From its base five minutes’ drive outside Ballarat, Albins Performance Transmissions has grown into one of the world’s leading transmission suppliers, one that exports to all corners of the globe.

Born from a need for spare parts and unable to find any suitable replacements for his vehicles, Albins began crafting his own components for his own personal off-road racers in the 1970s.

Word soon spread that Albins’s suspension parts for his buggies were the best available and far superior to anything else on offer.

So in 1978 Albins was established.

In the early days Albins built and serviced engines and gear transmissions for VW buggies and soon developed a loyal following with his fellow racers, who were lining up to get their hands on his components. Albins then transitioned into gear cutting and the manufacturing of upgraded gear kits.

With more and more orders flooding his workshop, Ivan Albins decided to purchase his own specialised equipment and focused his talents on his gear sets.

Shortly after, orders for his world class and innovative gear sets flowed in from the USA and soon Albins grew into a fully fledged business, sending precision racing parts all over the world.

Fast forward to 2016 and Albins has grown into a global supplier of competition racing components that are respected around the world, in both the motor racing sector and a growing business in the automotive industry itself.

Now operated by three partners, Steve MacDonald, Craig Geddes and Steven Nicholson, Albins has expanded their already successful off-road gear sets to the manufacture of street racing and drag racing gear kits, Supercar transmissions, high performance off-road gearboxes and even the development of off-road military applications.

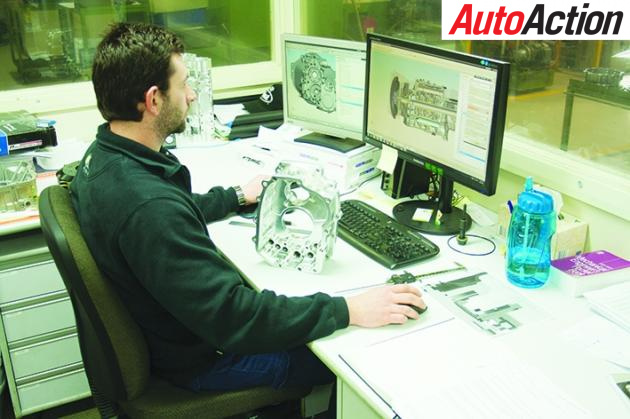

Albins designs and manufactures all of its components entirely on one site.

“We offer a full engineering service including initial concept design, systems engineering, component and assembly design using 3DCAD and CAE tools, as well as thorough life support with spare parts packages and service arrangements,” explains Craig Geddes.

Albins also offers a wide range of machine capabilities including: CNC turning, milling, gear cutting and CNC Gear Profile Grinding and specialises in the manufacture of Spiral Bevel and Hypoid gears. This type of gear is most recognised as the final drive gear set in a rear wheel drive vehicle. Albins employs a German system, Klinglenberg Palloid, for the manufacture of these parts and is the only company that has this equipment and capability in Australia.

Through the manufacture of such a broad range of high performance specialist driveline components, V8 Supercars awarded Albins the transmission contract for its Car of The Future.

“Landing the V8 Supercar deal was a great boost for our profile,” says Geddes.

“When the technical committee were developing the Car of The Future, the desire was to move to a transaxle for vehicle packaging and weight distribution. Albins was able to provide a solution that met all their criteria and was awarded the controlled component contract.”

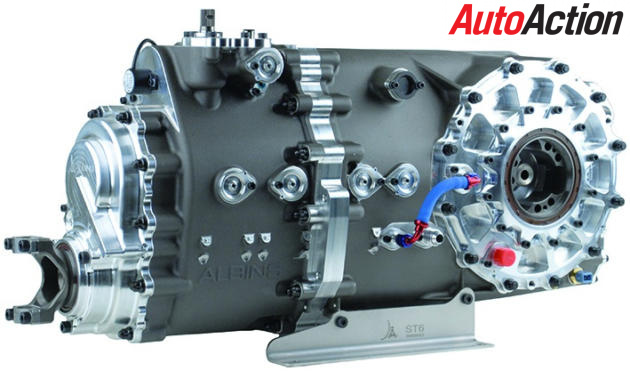

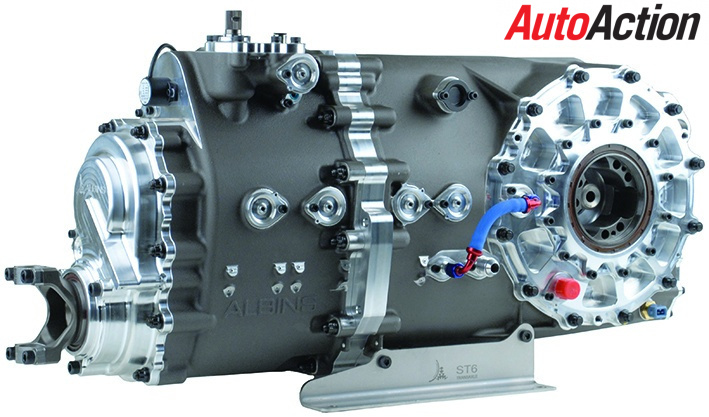

The Albins ST6 transmission was originally designed for the Australian V8 Supercar as a transaxle. It is a 6-speed sequential transmission that can be configured to an in-line transmission, rear-mount transaxle or mid-mount transaxle, providing a range of applications across a multitude of platforms. Nearly all these configurations incorporate a ‘drop gear’ arrangement that allows the customer to easily change the overall gear ratios for different tracks at a low cost. The volume of sales of these other variations is now much greater than the original application. Albins designs and manufactures this gearbox completely in-house.

Apart from being one of the company’s most visible products the ST6 transmission has also helped the company through a challenging economic climate.

“It was a few years after the GFC hit America and we were in a rebuilding phase after being affected by the downturn,” recalls Geddes.

“Prior to 2007 we were exporting 90 percent of our product through one distributor in the USA, and they were hit hard, so it was really tough.”

With the popularity of the ST6 transmission over various racing disciplines, Albins also offers its customers full servicing back-up.

“We also offer a servicing agreement with our transmissions to various race teams. This not only includes the labour to service the transmissions, but also full lifing of the parts and planning of all service activities. There are now a couple of V8 Supercar teams taking advantage of this service, which in years gone past was only entrusted to personnel within the teams. The service shop is proud to point out that the 2013 and 2014 FPR Bathurst victories were with transmissions prepared for The Great Race at Albins.”

Geddes says that Albins has no plans of sitting on its laurels.

“We invested heavily in new equipment to keep us ahead of the game and we will continue to invest in new technology and equipment going forward.”

Albins is also eyeing off the lucrative European market, where off-road auto sports are attracting more and more participants each year.

“Motorsport is very important to us and we plan to continue expanding into the European market, which we’ve identified as a major area of growth for our business,” adds Geddes.

“Rallying in the UK is huge and we have been supplying product there for many years. We’ve also adapted our ST6 gearbox to suit other applications, such as Time Attack and Drifting.”

Albins association with rally also saw them work alongside three-time Asia-Pacific Rally champ Possum Bourne throughout the 1990s and early 2000s.

“We also develop racing gearboxes for the Qatar Racing Club where they are fitted to Nissan Patrols and Land Cruisers, which compete in the FIA Cross Country Rally World Cup. They can withstand up to 2000 horsepower,” says Geddes.

If you thought the ST6 was the only high performance gearbox Albins developed and manufactured, you’d be wrong.

Their AGB series of transmissions have found their way into championship winning Baja and Dakar vehicles, while the AGB 10 and AGB 11.5 models are also available for even more extreme punishment.

Albins distributes its AGB and ST6 series of transmissions through Weddle Industries in the USA and have a loyal following in most professional off road disciplines there.

The AGB 11.5 enjoyed success in 2009 and 2010 as The Best in The Desert Unlimited Class Championship, as well as Class One victories in the Baja 500 and Baja 1000. This transmission is regarded as the benchmark in off-road racing and is exported the world over.

While the Albins brand enjoys established markets in the off-road and Supercar scene, it also offers the AX35, a complete bolt-in replacement transmission for Nissan R35 vehicles.

From initial computer dot point imaging of the Nissan’s undercarriage to assure a perfect fit, to the early CAD drawings, to the creation of parts, gear-testing, final fit and eventually the testing process are completed entirely on the one premises which gives Albins unrivalled control over all of their products.

Albins also offers replacement OEM gear sets for the R35 GTR Nissan, Honda K and B type, Subaru WRX 5 and 6 speed, Mitsubishi Evo II-X, Porsche (including 911) as well as Nissan L Series and Patrol GU.

With the Ballarat facility now employing more than 50 highly skilled experts – within what looks from the outside to be a modest building – and with some tough times behind it, Albins looks to be a name that will continue at the forefront of the sport, in Australia and around the world.