Under the Skin: Thunder 5000

After two years of development Chris Lambden’s Formula Thunder makes its public debut this weekend. PHIL BRANAGAN takes a look at Australia’s latest open-wheeler.

Motor racing in Australia is, by world standards, pretty good.

We have international events in Formula 1, World Rally, MotoGP and World Superbikes. Our Speedway and Drag Racing arenas are pretty entertaining. Our domestic racing is world-class, headlined by Supercars, one of the best domestic sedan racing series on the planet.

But, there is something missing. There are no big banger racing cars.

Americans have IndyCar. In Europe, and around the world, there is GP2, and Formula V8 3.5 (which used to be called World Series by Renault). Super Formula continues to roll in Japan.

But in Australia, there is none of that. You get to Formula 3 and, if you want to go faster with wheels you can see, your head hits the ceiling. If you want to race a big, powerful open-wheeler, the only similar class is Historic Formula 5000.

No more. Formula Thunder promises to change all that. As previously detailed in AA, Chris Lambden has been working on this concept for more than two years. now a prototype is running – and has completed its shakedown test at Winton.

This weekend that process continues. The car will make its public debut at Sydney Motorsport Park, as a part of the Muscle Car Masters. With a carbon-fibre tub, a Ford ‘Coyote’ V8 engine and 560 horsepower, the car promises to be something quite spectacular.

We sat down with Lambden and Borland Racing Developments’ Michael Borland to talk about the development of the car.

But first, there is an elephant in the room. When Lambden went public with the car six months ago, he announced he was anticipating the car would test in late-May. It made it onto the track on October 10.

“Some things take longer than anticipated,” he says. “In my case I was probably a bit optimistic.

“As we went along the key people said, ‘We might just tweak this and change that’. For example, we made a few changes along the way. Holinger wanted to make some changes and their input was key. Their input took a bit longer than we thought it would, so we made the decision that it would take as long as it would take – and when it was ready, it was ready. And when it was ready, it would be 100 percent.”

So it proved. In the course of doing all the things that happen at the first test of any new racing car – from making sure that the wheels go around to changing gears – nothing went wrong.

Borland puts it bluntly; “The first test day didn’t scare the shit out of driver. That is what a first test day is about, make sure the data stuff works, that it changes gear.”

The concept of the car has received wide acclaim but one thing that Lambden wants to underline is the philosophy behind the project.

“This is not an attempt to make a modern Formula 5000 car,” he says. “It’s more, ‘if we were going to build a really hot racing car, what would we do?’ V8 engine? Tick. Big fat tyres? Tick. Coincidentally, it has used some of the same philosophy from that era. But we wanted the best, cost-controlled racing car that we could make and that is why we have ended up with things like the paddle-shift gear change.

“It was never specifically meant as a modern F5000 car. But a fair bit of the philosophy comes from that era.”

The basis of the car, as has been reported previously in AA, is the Swift chassis that was raced in Formula Nippon – now known as Super Formula – in Japan, and which was replaced at the end of the 2012 season. It was, at the time it was raced, a state-of-the-art car.

“The car, as it is built, is pretty complicated,” explains Borland.

“It was built to a high spec because that is what they wanted. I think, because Chris bought all of the running gear, that is what we’ve stuck with. I think that we will simplify components, and limit some of the adjustments that can be made, to make it cheaper to make and easier to work on. Chris wanted something that made a good noise and went sideways, and was going to be economical to run over a couple of seasons. You do not want a team of mechanics servicing gearboxes and hubs and so on.”

On closer inspection, some things look more simple. The hubs are the same front and rear and the front suspension is the same as it was under FNippon, save for putting a bigger tyre on it.

“The front, we couldn’t do much with,” says Borland, “the mounting points are already built into the tub, and the uprights are what they are. Even so the tyre size change, we had to run what we were given. The rear, we had a bit more scope. The size of the rear tyre changed dramatically. That lifted the rear of the car up substantially so we had to change a lot of the rear of the car.”

But one area that is much different is downforce. A FNippon has a lot, and on soft tyres could lap Suzuka within a couple of seconds of a F1 car. For the new car, modifications were made.

“Chris wanted less aero on the car,” says Borland. “The rear wing is exactly the same, the sidepods have been cut down, probably, to about a third of what they were. The front wing has just been made simple, compared to the original. That trimmed a lot of the downforce off the car. I think that car has about 50 percent less downforce.”

Put simply, from the roll hoop forward, most of the car has stayed the same. From that point back, it’s different.

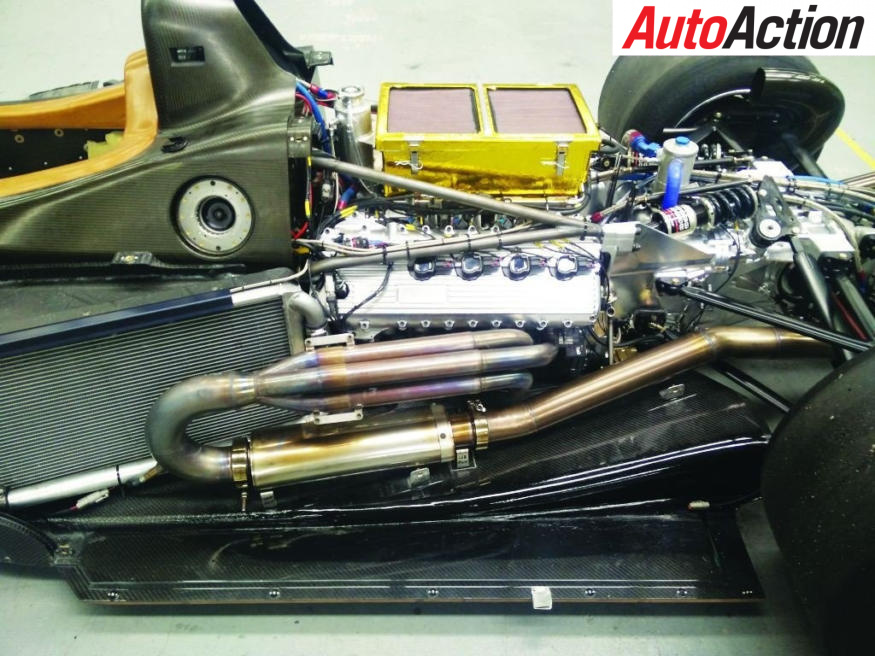

The biggest change is, of course, the engine.

“One of the key people has been Roger Higgins,” says Lambden.

“We set him the task of identifying the best possible engine, in terms of cost and aim, so on. He came up with the concept of using the Ford Coyote, which he had a fair bit of experience with. He did a really good job, and it’s been a great result. He makes the fuel injection system, and it works really well.

“We had started off with one of the earlier model engines and then a new one came out! Neither Roger nor MoTeC had run this version, which is called the Aluminator, so that was an unexpected change we had to make. It has better cylinder heads and makes more horsepower. Some of the modifications we were going to make to the older engine, we do not need to make to this engine.”

The bottom line is, 5-litre aluminium four-cam, 32-valve V8, with about 560 horsepower. The package is now well-known to many in the sport, but the electronics are much different.

“Originally the car had PI electronics,” says Borland. “The car had a cable throttle, so we went to a fly-by-wire throttle. It was a paddle shift before, but it was a pretty early version of that, which had to have a ‘blipper’ motor in it.

“That has been one of the biggest things; the car is an eight-year-old design, so safety-wise, things have not improved that much. Mechanically, things have not improved that much. The biggest thing is the electronics in the car; they have changed a lot in that time.

“It sounds simple. You go to MoTeC and buy the bits that you need. The first R&D car will have an M150, but this has an M180, because of all the bits and pieces that you need to do. Things like, MoTeC does not have its own steering wheel to go inside this car. They have one for a GT car – so we had to make our own steering wheel. That, and fitting the paddles to that,

take longer than you think.

“And making a fly-by-wire throttle, that takes time. It needs to fit into the pedals and so on. It is complicated to start with but it extends the life of the gearbox.”

Originally, the car’s motor was fitted as a stressed member – a role that Ford engineers never had in mind for the Coyote. The new engine is mounted to the original pickup points, but also has two additional struts, to triangulate the load.

“It’s a bit big for the chassis but it ended up fitting up quite easily,” says Borland. “At the end of the day the engine was not designed to take that kind of load, so we tried to take that load off it, to increase reliability.”

Lambden continues, “In terms of mounting the engine to the tub we utilise the same top and bottom mounts on the tub as in the original car. The dry sump goes forward to the bottom mounts and the cam covers mount on the top mounts. So far, that has worked perfectly.”

Much of the work that has been done at Borland’s HQ has been straightforward, according to the man himself.

“Our engineering part of it was simple; design new rear suspension and exhaust systems, plumb the car up… that part of it was no different to what we normally do,” Borland says.

“I haven’t had to deal with outside suppliers with my Formula Fords to the extent that I have had to with this. There has been a lot of external input with this, Holinger’s especially. That is not difficult, but it takes time. Holinger’s were outstanding; they were always thinking two steps ahead of where they need to be.”

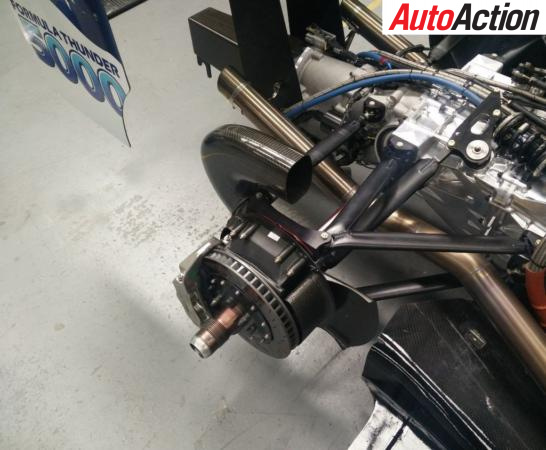

And the gearbox, in some ways, is the centrepiece of the car. Holinger Engineering was involved with the project from the very early days, and they have played a major role in the car’s development. The internals are a customised version of the six-speed sequential Holinger MFT transaxle, which is widely used in Porsche racing applications.

“To adapt it to what we have here they had to change the front of the gearbox, to mount it as low as possible,” says Lambden. “So they made some drop gears to facilitate that, and in conjunction with Michael and Roger Higgins at InnoV8, they made the bellhousing. That is just a work of art – it has a full integral oil tank and suspension pickup points.”

The specs for the car’s suspension and braking systems are being finalised – the type and even brand of both may change in the production cars – but the tyres are locked in. Giti has been involved with the project from the early days and its big tyres certainly look the part. The fronts are the brand’s existing rear F3 tyres, and the rears are custom-made.

“The local agent is Russell Palmer from Motorsport Tyres Victoria,” says Lambden. “He has a very good relationship with Giti and he has played a very important role in bringing the whole thing together.

“The wheels are made by a great little company in Auckland called Arrow. Lots of people – for instance, Historic F5000s – use their wheels. They are three-piece, which is a great thing if you damage an outer piece, you do not throw the whole wheel away.”

And the final piece of the equation is the airbox. The car came with low rear bodywork but that has been replaced by a high, 1970s-style airbox, reminincent of many of the Lolas now seen in Historic F5000. The current unit is in fibreglass; production versions will probably have carbon-fibre units.

“The airbox is a love/hate thing,” says Lambden. “Some people go, ‘WOW!’, most people do that. Some of think that the retro look is not their cup of tea but I think that is running about 90-10 at the moment.”

So, the vital question… how much will the cars cost?

“I think it will end up about $270,000 plus GST,” says Lambden.

“If we find a few things that require an adjustment to that, that is what we will do. The whole thing is designed to be as affordable as possible. Compared to some of the other categories in motorsport, bang for buck, this will be pretty good.

“We are poised and ready to go. This whole project revolved around the fact that we have obtained all the designs and moulds from Swift Engineering, to use as the basis of our car. We have all that stuff here at Borland Engineering. The next crucial step is to demonstrate the car and to have the motorsport community say, ‘Yep, that’s what we want’.”

The other common query is, when will the cars race?

“The primary target has always been a summer series, which would mean next December/January [2017/18],” says Lambden. “But we want to have two or three one-off events, from about the middle of next year, to get people who want to run the car together.”

A step in that process starts this weekend at SMP, which seems to be the perfect venue for the car to impress. The success or otherwise of any motor racing category is how they are embraced by the people who matter – the prospective drivers and car owners. So far, the feedback has been largely positive – but customers have not been asked to commit yet.

Now, they will be. The signs are good and the sound of Thunder is getting closer. Can you hear it?

Macrow Management

Only one man has driven a Formula Thunder. AA asked current F3 champion Tim Macrow for his initial impressions.

“Straight out of the box, the car has been absolutely bulletproof. That actually allowed us to do some set-up work.

“The gearbox has been great. Great gearchanges, the brakes are fantastic and everything works. It will move around a bit, and there is plenty of horsepower. It will be a bunch of fun to race.

“It has pretty good balance, right out of the gate. It has enough downforce to give people confidence in the car but little enough so people will be able to race nice and close. There is still a lot of set-up work to do and we will improve the car out of sight once we get a proper set-up from testing.

“It’s probably a bit closer to a Formula Atlantic that I drove in America. That was a ‘tunnel’ car and this is essentially a ‘tunnel’ car as well. This is a bit bigger and it has a fair bit more horsepower. It has something in common with a Sabre-Buick, a 1990 IndyCar that I drove. In a way, it’s like that – big power, big wheels and tyres. I can’t wait to go somewhere like Phillip Island and stretch its legs a bit.

“The engine was so smooth – that is what struck me. If you push it hard enough you can lay down liquorice strips pretty easily but the power is really smooth and it sounds awesome. Apparently they could hear it in Benalla! It is exactly what Chris was looking for in the sound department.

“It is something to aspire to. All the open-wheeler categories in Australia are ‘junior’ categories, for developing drivers. I am hopeful that this might be an aim for a few people. Hopefully people will buy the car and enjoy racing it.

“After doing the initial testing, I would love to race one!”

PHIL BRANAGAN