UNDER THE SKIN: NZ TOURING CAR – DOCTOR FRANKENSTEIN, I PRESUME

Under The Skin of NZ Touring Car Frankenstein Falcon/Camry

Across the Tasman some clever Kiwis have come up with a Touring Car Series that provides good racing, is affordable and have a variety of makes – and has one car with two makes…

By PHIL BRANAGAN

YOU HAVE probably heard the story before.

Two groups have their own idea for a motor racing series. Both see strengths in their own ideas, and weaknesses in the other’s. Both back their own plan, race for a while, until the grid shrink and neither succeeds.

Except, in New Zealand.

That was the landscape in Touring Car racing in NZ only a few years ago. One group had a series for V8-powered Commodores and Falcons with a common engine (LS7 Chev), a kind of down-scale version of V8 Supercars. The other group had something similar, but with the DNA of the engine to represent the manufacture, ( Ford body Ford engine, Toyota body Toyota engine, etc). Both groups raced on their own but, so long as there were two smaller grids, neither were likely to be successful in the long-term.

It is now well-known that there were actually three groups active across the Tasman and that they combined a couple of years ago into the BNT NZ Touring Car Series. There are three classes of cars but the grids are full-ish and the racing is pretty good.

But Under the Skin is about how and why the cars are built, so we have picked one of the cars in the series. Jason Bargwanna drives for Richards Team Motorsport in a Class One Toyota Camry – almost. As the car raced last season it was part-Toyota and part-Ford, and as Richards Team Toyota team principal Stephen Richards explains, there is a good reason why.

“We originally built two Camrys,” he says. “Bargs brought Scott Taylor over to drive in one of the seasons – a season and a half, actually – a couple of years ago. Scott bought the Camry he was driving and took it back to Australia.

“Not long after that the original TLX Ford that was built, and that was the first of the chassis that we were running, came up for sale and we bought it. It had the Ford Boss Coyote motor in it, but at the first round – the Supercar meeting at Pukekohe in ’16 – we were battling a few engine gremlins, with electrical plugs coming out, and oil temp issues in which it finally collapsed an oil filter and ran the bearings.

“We got home and it was obvious that it was a better option for us to put our spare engine in there – and that was a Toyota. All we had to do was change the car from the windscreen forward, so we did. The front guards, bonnet and bumper went on and we completed the season.

“As I speak now we are putting the rest of the Camry bodywork on for next season. It will be a ‘full’ Camry.”

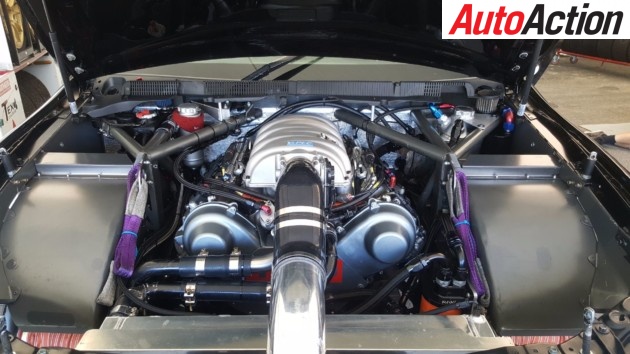

So ignoring the fact that the car was a bit of a Frankenstein last year, there are a lot of interesting things in the car, starting under the bonnet. With Class One cars catering for Chevrolet LS7-powered cars, as well as two and four-valve configurations the Camrys run a motor sourced not from New Zealand or Australia but the land of the pushrod, the USA.

The Frankenstein car as race by Jason Bargwanna

“The engines were built for the Daytona 24 hour Grand Am Prototype series in America, by TRD [Toyota Racing Developments in California] which was run under the Lexus banner by Chip Ganassi Racing,” Richards explains. There were drivers like Juan Pablo Montoya and Scott Pruett involved who were very successful in the series.

We didn’t want to start again, these engines were already developed and there is a lot of cost involved in starting a racing engine program from scratch. As they were they were not ideally suited to what we wanted. it was the only engine option that we had available.

The smart part of the equation is how equality is achieved between the wildly differing types of motors. Like the Toyota team, the Nissan Altima uses a four-valve DOHC engine, which is the same base engine as Nissan is running in Supercars, and which the team is developing that themselves.

The TRD developed Toyota 5.0L engine

How do you get a 7-litre Chevy, a 6.2-litre Holden, a 5.4-litre DOHCs from Ford and Nissan and a 5-litre Lexus motor to compete on equal terms?

“All the engines are tuned through an E-throttle,” originally by Andre Simon at Speedtech Motorsport in Wellington and now by Dave Heerdegen At DTech Motorspot in Tauranga, says Richards. “They get an equal power and torque curve across the range and it works really well.

“In a sense, ‘parity’ is not a correct word to use but it might be the only word you can use. It is actually ‘sporting parity’, and that means that all the engines are tuned so that the power / torque curves are as close as you can get them at the wheels at the appropriate RPM. It is within less that one percent, and it works well.

“With our engines, that means that the drivers can use 100 percent throttle. With the LS7, which is much bigger, it uses only 64 to 68 percent of the throttle.”

So what you see is the cars running on the straights, and top speed is about equal, on varying throttle positions. In a 5-litre quad-cam that means full throttle; with the LS7, only two-thirds throttle.

One thing that is not really an issue – not as much as it is in Supercars races anyway – is how much fuel is used.

“Fuel consumption is not an issue, we are only doing Sprint races,” says Richards. “But if you get your calculations wrong, it’s like anything else, you can run out!”

All of the cars use a fuel system with a maximum capacity of 100 litres.

The E-throttle appears to work well, but that is not the only item governing the cars’ speed. There other is the gearing there are slight differences between the different engine profiles.

“We have set ratios in the ‘box, but we have slightly lower first gear,” says Richards. “That is to help the multi-valve engines get off the line. The other ratios are all the same.

“The diff ratios are also set, on a multi-valve we run a 3.7 (to one), the two-valve engines like the Holden and the Ford, they run a 3.5. The LS7 engine runs a 3.25. Together with the rev limiters, the tops speeds are identical.

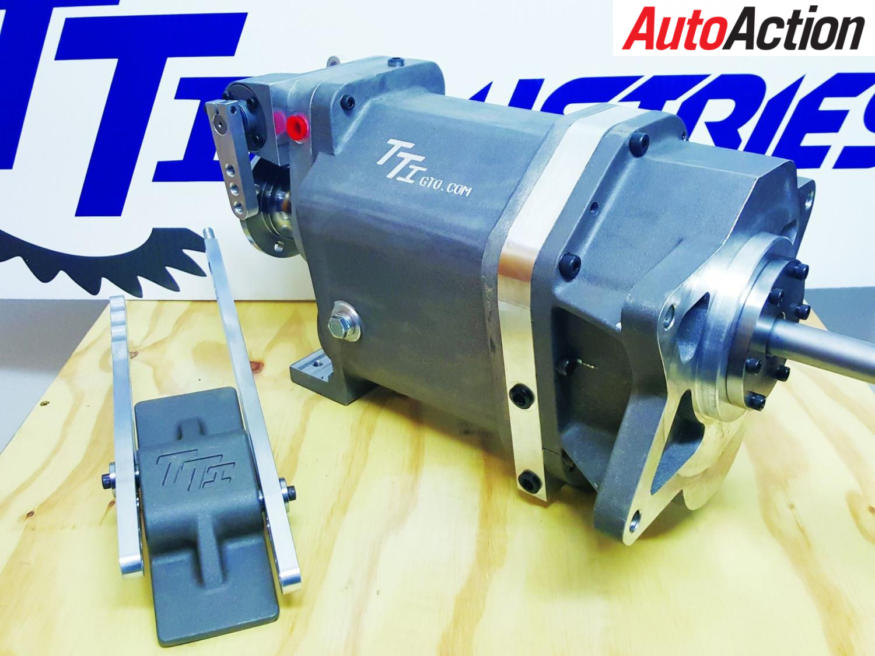

TT Industries 6-speed sequential gearbox

“The best interests of the sport are taken care of. You only really get true parity with identical cars, and these cars are different – different shapes with different engines.”

So far, so good. There are differences on the chassis side as well. The V8 SuperTourer cars are built around a chassis made by Pace Innovations in Queensland, which is similar to the previous generation V8 Supercar chassis. It uses a Quaife six-speed gearbox and has Brembo brakes.

But in the TLX class, in which the Camry races, it is much different. The cars were built around a locally sourced chassis built by Mitchell Race Xtreme (MRX), based in Horotiu, near Hamilton in the North Island, and run by father and son, Derek and Nick Mitchell. In 2011 they designed the universal chassis for the cars – with pencil and paper, not a CAD computer in sight – in nine days. Since then seven have been built, and six are still in NZ, plus the Taylor car, and all have proven reliable and safe.

“There have been a few little problems, as there are, but nothing of any consequence. The chassis have been fantastic,” says Richards.

“There have been a couple of crashes, three years ago we had AJ Lauder driving the car that Scott now has. He went off at the end of the straight at Manfeild at full noise at Turn 1, and all of the crash crumple points worked perfectly. We stripped the chassis from the firewall forward and had MRX cut the front chassis section off and put a new one on. It was perfect.”

The controlled MRX spaceframe chassis

About now you might be starting to think that there is a lot of thinking in the cars that are similar to the Project Blueprint generation of V8 Supercars…

“The rear end is three-link suspension, with a nine-inch diff,” says Richards. “It’s a solid rear axle, with a spool diff. The front is wishbones, with Penske 2 way shocks, which are controlled. At the moment springs are free, there are no restrictions on them. We probably have two or three sets of front and rear springs each, once you are in that window you are not going to make big changes.

“It was discussed quite a bit, because of the different engine weights. It would have been difficult to have one spring at the front that everyone could use, and there was some talk about one spring being nominated for each car. But it was finally decided that there were more important things to worry about than a control spring.”

Only single springs are permitted – like in the Dunlop Super2 cars; twin springs are not permitted.

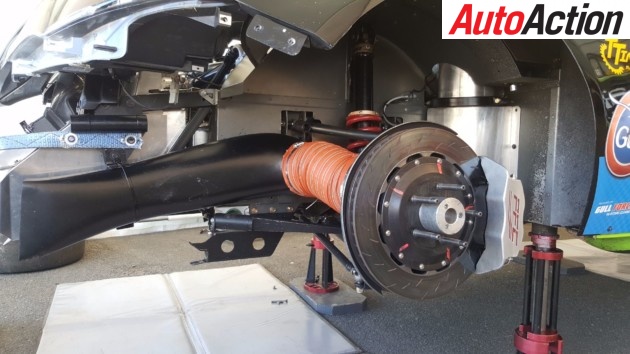

The brakes are off the shelf items and here there is a little bit of wriggle room.

“We started out with only the PFC brake package, but also what is allowed now is the Brembo package that is run on the Super Tourers,” says Richards.

“When we purchased the Falcon it had Brembos on it, they were brand new but Bargs couldn’t quite get the modulation right. There were some other things that we were trying to sort out at the time, so we ended up putting the PFCs on. That was a known quantity.

PFC 355x32mm front brake package

“If we were going to do a lot of endurance races I would imagine that the Brembo package would be better. Our summer series races are mostly 12, 14 and 20 laps, and on our circuits that would be 60 to 80km.”

One difference that the car has to a Supercar is its transmission. The Project Blueprint cars used a Holinger six-speed box for years, until the COTF moved to an Albins ‘box. The V8SuperTourer runs a Quaife but the TLX cars use a locally made unit.

“The gearbox is a TT Industries six-speed sequential, built by TT Industries in Nelson,” says Richards.

“I think that they have been building racing car gearboxes for six or seven years. Bruce Verdon, who started the business, started off building gearboxes for motorcycles. He brought a six-speed box up about six years ago and we fitted it to one of the old cars, and we tested it for him. It’s very good.”

There were few teething problems early on with the transmissions which can be expected with a new product of which were all repaired by the manufacture. The last 3 seasons reliability has been excellent. They are also available in four and five-speed versions as well as four & five speed H pattern. Bargwanna states that the unit is “as good as any I have used”.

In the wheels and tyres department it is back to the Supercars songbook. The wheels are 18 inches and are fitted with the same Dunlop tyre as Supercars. It’s the harder tyre, the same size, 18 inches and 680mm.

“When the cars were built by Mitchell Race Xtreme all the car’s pick-up points, the geometry of the chassis were similar to the last generation of V8 Supercars – with the gearbox in the middle and the nine-inch diff at the back.

When we were at Pukekohe, the first time we got these cars going, Ross and Jimmy Stone were there then and in the pitlane they had a good look at the cars, and they were impressed.

“There are a few people around that think that this is what Supercars should have stuck with. The current Supercars are great race cars but they seem to be a little bit fragile when the rear wheels are rubbed.

“I can see a bright future for the series. Speedworks has taken over the promotion of the series, and Geoff Short and his team are doing a good job. It is a little bit like looking at someone in politics; some people love the man at the top and some hate him. They have the interests of the sport right at the top of the list of priorities.

Inside the Toyota-Ford hybrid

“They want to run some endurance races in the series next year on the Saturday afternoon, with up to 12 NZ V8s, 12 GTs and 12 Porsches, at four rounds of the championship. That will be a one-hour races, with two drivers or a single driver, with timed pitstops.

“The future looks good, and the series is a good place to be.”

So the elephant in the room is cost. How much?

How long is a piece of string?

“I think that it would be a fraction of what it costs to do Supercars,” says Richards, who quote all number in NZ dollars.

“To do one round… an average would be, over six rounds, in round figures, between $15,000 and $16,000 plus GST per round. So for the season, with getting the car prepared for the season, would be about $30,000 plus GST per round. That takes into account freshening up the engine, rebuilding the gearbox, everything to prepare for a new season. So six rounds, about $180,000 plus GST per year – and that is everything excluding damage.

We don’t cut corners, and if a paying driver walked in with a helmet, that would be a starting point of what they would need.”

It is still relatively early days for the ‘combined’ series. What happens across the ditch is not Supercars – far from it. But it is an example of what can be done by a group of people who see value in bringing together two seemingly disparate groups into one unit.

As the series moves forward the future will be built on more common ground than has been under the feet of of those who got NZV8s to the point they are now.

It’s kind of crazy that there was a Toyota-Ford hybrid in the series, even if it was only for one season. There won’t be any more, but the fact that there was, even for a while, a ‘Falcamry’ on their tracks shows that our Kiwi cuzzins still have a fair bit of ‘can-do’ and common sense about them…

TECH SPECS

Engine: Toyota 5.0L, developed by TRD

[Also usable, Nissan 5.4L, Holden 6.2L, Ford 5.4L]

Horsepower: 560

Chassis: MRX spaceframe, control

Wheelbase: 1820mm

Track [Camry]: F 1930mm/R 1905mm

Body: Manufacturer dependent – Toyota Camry, Holden Commodore, Nissan Altima, Ford Falcon

Gearbox: TT Industries 6-speed sequential

Diff: 9-inch Ford

Brakes: PFC 355x32mm front, 232x28mm rear ventilated rotors

Shocks: Penske shock absorbers

Weight: 1370kg with driver

Onboard Computer: MoTec

After Auto Action’s latest Under the Skin feature? Pick up the current issue of the magazine, in stores now. Also follow us on social media Facebook, Twitter and Instagram for all the latest news.