Under The Skin: Audi R8 GT3

AUDI’S CUSTOMER MISSILE

Since its debut in 2009 Audi’s R8 GT3 racer has won races of all lengths, all around the world, including Australia.

Whether you gauge success by the number of races a car wins, or by the number of different models of the same car are winners, you cannot call Audi’s R8 GT3 racer as anything but a runaway success.

In three different versions, the cars have become one of the benchmark performers in GT racing all around the world, in various series, in many different countries. The exception is, of course, the Le Mans 24 Hour race, in which no cars of the type appear because Audi has bigger, Hybrid, diesel-powered fish to fry.

Initially eight cars were built, but with plans to build as many as 35 a year after that. The first car was delivered to Audi Sport Italia for the start of the 2009 season and it was soon obvious that the capacity to build cars at the Neckarsulm factory was going to be needed.

Seven years on, the car is a great seller among customer teams, with 136 of the older R8 LMS and R8 LMS Ultra, and 60 of the new 2016 R8 LMS, being delivered so far. Add to that the prototypes involved in the development of al three variants and the number of actual cars is 200-plus.

Those numbers have been achieved remarkably quickly. The 100th racecar from the Heilbronn-Biberach factory was handed over to MS Racing in April 2013. The 200th went to the rather awkwardly named Team Montaplast by Land-Motorsport, to be raced by Christopher Mies/Connor De Phillippi, in July this year.

In other words Audi is rolling out R8 GT3s to customers at almost twice the rate that BMW’s M6 GT3 is finding new homes. BMW has built 20 M6 GTRs and Mercedes-Benz’s GT3 (which technically is an AMG) has come in a batch of 24 cars in its first year.

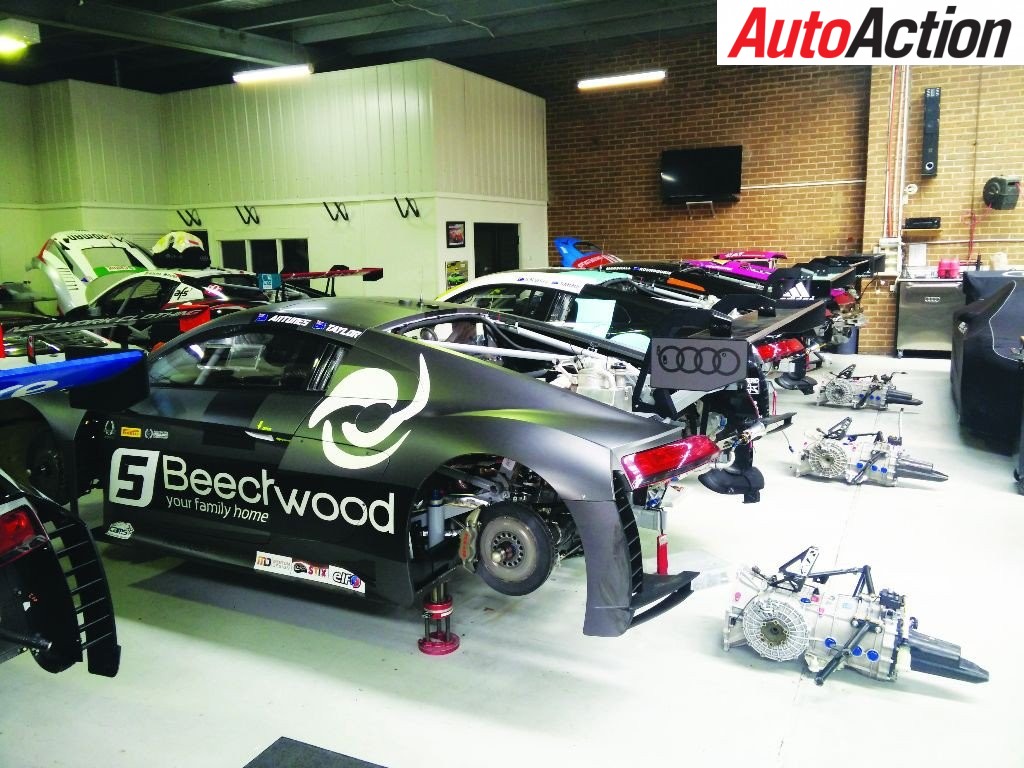

Compact MPC workshop plays home to up to 15 R8s of various specs, as well as other cars.

Part of the reason for that is the track cars produced at the Böllinger Höfe site on the same manufacturing lines as the production model.

It was hardly a surprise when a racing version of the R8 was announced. The original prototype road car was shown in Frankfurt in 2003, and named the ‘Audi Le Mans quattro’.

The first version of the production model of the car broke cover in 2008, and captured a fair degree of attention. The roadgoing car’s quattro AWD system was deleted for obvious reasons and the track version – which was designated ‘R16’ within the Audi Sport system – was Audi’s first large-scale ‘customer’ GT3 racer. Long-time Audi driver Frank Biela took the role of lead development driver, alongside Frank Stippler and Christian Abt and, with the involvement of long-time Audi ally Abt Racing, work began in January of that year, a remarkably short time frame.

There were a lot of clever ideas in the car, from the start. The wing profile, for instance, came straight from the Le Mans-winning R10, which Audi knew worked, so the shape was transferred straight to the GT3 car.

The racer was built around the road car’s original aluminium space frame (which weighed 210kg) but the road car’s aluminium panels were replaced by more ‘raceable’ versions made of composite material. The road cars weigh up to 1600kg; the racer is down around 1225kg, depending on the BOP stipulations.

Melbourne has become one of the epicentres of Audi’s GT3 racing program. The outer eastern suburb of Bayswater is home to as many as 15 of the beasts, watched over by Melbourne Performance Centre principals Lee Burley and Troy Russell and 11 full-time staff. During events that number grows; for instance, MPC takes as many as 60 people to Bathurst for the 12 Hour.

Mark Eddy was the first customer to bring a car down under in 2010 and Audi was keen to see more – particularly after a 1-2 finish at the 2011 Bathurst 12 Hour, the German-run car just beating the Eddy/Craig Lowndes/Warren Luff entry by 0.71s. So Audi Sport Customer Racing was born from that experience and is now the sole Australian supplier of all Audi Sport racecars and spare parts.

The first 2016 version to appear in Australia was Ash Samadi’s at Townsville in July – and at the time he stated that one of the reasons he decided to switch to an Audi after racing a Mercedes AMG SLS GT3 was the reputation that MPC had built up.

The key to the expansion in numbers has been, according to Russell and Burley, the firm’s willingness to support its customers – for instance, sending spares to Australia on consignment so neither the car owners nor MPC would need to reach into their own pockets. That has been a major shift; even when Audi was involved in Super Touring racing in Australia, its involvement with Brad Jones Racing was much more as a ‘works’ team than a customer relationship.

Interior has to cope with many different size drivers, up to 190cm-plus Steve McLaughlin.

MPC provides backup in all areas and runs two full-sized transporters built to similar standards as in Supercars – include a PH Motorsport B-Double, complete with driving simulator, in case drivers want to tune-up before they get into their cars…

Since the first racer appeared in 2010 there have been plenty of changes, Russell explains.

“In 2011 they upgraded the chassis, based on a weakness that in the rear they found in the design of the road car. That was an upgrade in ’11, and in late-’11, they put on slightly more aero.

“In ’12, they put on a slightly wider front tyre [Ed: from 11 inches to 12], when they put on a wider track. There was also more aero, and again in ’13, with less drag and more downforce. That was the last evolution for that generation, and that froze for three years – ’13-’14-’15.”

The older version of the R8 is now eligible for the Trophy class in the Australian GT championship, and when in 2016 the new road car came out, the racing version was much different. It was still based around the same all-aluminium space frame, but it was built to a much different recipe.

Rear brake setup is serious.

Russell continues, “That was when, I believe, they had looked at what the other manufacturers had done and realised that they had been building racecars, rather than modifying road cars. Chassis-wise, it is still standard road car chassis, but the suspension arms are chrome-moly; there are billet uprights; there are a lot of things that have changed from the road car side of it.”

The changes were immediately apparent in testing.

“The new Audi R8 LMS is a real racer,” said Marcel Fässler when the car was launched.

“In the past the organisers wanted to have GT3 cars too close to their road cars counterparts. That was the case of the Audi R8 LMS ultra, a great car but too close to the Audi R8 road going model. Now we have a true racecar with a lot of improvements.”

Such was the amount of ‘racer’ built in to the road car that 50 percent of the parts are interchangeable, far more than the previous generation.

Russell continues, “There are two main advantages with the new car; cheaper running costs, because a lot of parts have had their lifing changed. With some parts, their life cycle has gone from 5000km to 7500 or 8000km. With driveshafts and other stuff, you are getting up to 50 percent more life out of a lot of parts. The gearboxes are much better; they have much cheaper running costs.

“The secondary thing was to make the cars reduce the gap between the ‘Pro’ and the ‘Amateur’ drivers. The key to the ’13 car was that the aero was so good that the Pro driver could utilise that but for the Amateurs, aero is hard to get your head around, and once you get into a slide, you lose all your aero – you get yourself into trouble. So the ‘Gentlemen’ drivers didn’t have a lot of confidence. So the new car has slightly less downforce – not a lot – but it is more efficient.

“The car is also more comfortable. The pedal box slides backwards and forwards; the clutch is automatic. So it is cheaper to run and easier to drive. For Balance of Performance [BOP], there was no point making the car faster. The old car was about as fast as it could go. The new cars are a lot heavier; we run the smallest restrictors. If we take those out, at Phillip Island, the cars are 1.8 seconds faster. To get to the homologated weight we need to put in 25kg of ballast. To get to the BOP weight we need to put in more again. With the old car, you struggled to get to the minimum weight.”

The FSI V10 engine remains largely unchanged, and its longer service intervals make it a relatively inexpensive power unit.

“Engine life, 10,000kms is the first service – and that is a bore scope inspection, replace the fuel injectors and a new harmonic balancer,” says Burley. “That’s it; we don’t even pull it apart. With testing and stuff, that is a whole season.

“At 20,000k, the same again; harmonic balancer, valve spring, retainers , conrods but still the same crankshaft and pistons. We could do all that locally but we choose to send it to Germany. It is a lot about, a manufacturer makes that service available and as soon as you start messing about, you do not want to put that on Audi. For the cost, we probably could not do it any cheaper anyway. It’s about $30,000 and that includes airfreight. You put it in a box and it turns around in about three weeks.

“The gearbox, we inspect that at about 6000km and the components are about 10,000km. We find a few things, something, with some small items getting some bruising, but not the gears or the dogs or rings. The internals are by Hoer.”

The gearbox is operated pneumatically, by a system based on the diesel-powered R10 LMP1 car, in a roadcar gearbox casing but with a different 4SA transmission by HÖR in Weiden, Germany. The older cars have Holinger internals, and both transmissions have six ratios, one less than in the road car.

The first version of the car sold for 262,000 euros and the newer car can be purchased for 359,000 euros, which translates to about $650,000. More than a Supercar? Maybe. But of course, the business model of the two categories is much different, with much of the build of a Supercar taking place in-house, whereas a Customer program takes a race-ready, factory built car, with similar parts, and delivers the lot.

In the words of long-time V8 Supercars engineer Erik Pender, who was the Kmart Racingengineer behind Greg Murphy’s famed ‘Lap of the Gods’ at Bathurst 13 years ago, and is now with MPC, “it is much different. With this, even the cable ties have part numbers!”

Gentlemen and ‘Others’

One of the features of GT racing has been what level of performance Professional drivers and Amateurs get out of the same cars.

It would be easy to assume that the driver aids are set much differently for full-timers and gentlemen but that is not the case, according to Troy Russell.

“Traction control and ABS are not about driver feel, it’s about how much grip you’ve got,” he explains.

“On a grippy track, you can turn it down quite low, in different conditions, you need to turn it up. Our Pros and Amateur usually run the same ABS mode; the Traction control mode, you run the Pros, probably, one step down from the Amateur. It’s not like the Pro is on 1 and the Amateur is on 6, or something. There will be, like, 1 and 2. That is used as a tool for tyre management and weather conditions, but the Pros and the Amateurs are about the same on settings.

“If you are down on 1, you can get a bit of a slide on. If you are up high, you drive around thinking that it is all very stable – then you hit a bump and ‘whooofff!’. The settings cover up a lot of that but they can’t cover up everything. That is when you go sideways.

“On 1, you are on the edge, but it helps to manage it. It is not stability control like a road car.”

Lee Burley points out that the capabilities of many Amateur drivers have evolved and that the 2016 R8 GT3 is, for them, a much better tool.

“The Amateurs are doing so much testing now too, they are much closer to the Pros,” he says. “To win Bathurst – well, up until this year, because there was not a Pro-Pro category [before] – it was all about the Am driver.”

“In the old car, our Amateurs were over a second faster in the new car at Phillip Island. The Pros were a couple of tenths faster.”